First ever Restoration - Suffolk Super Colt - Lots of questions!

Hello all, I've been browsing the site more and more recently - mainly from search results while googling for information. After giving up cycling recently due to health problems i needed something to help pass the time and something to fettle with! I've always carried out servicing and repairs on my own cars and bikes, learning along the way and reading up about things i didn't know how to do, and like to think I’m mechanically competent.

There has always been something about engines that has intrigued me, and so i decided to see if I could strip down and refurbish a lawnmower. One came up nearby on the bay, a 'Suffolk Colt' which was advertised as spares / repairs due to 'No Spark - suspected coil'. I figured it was worth a punt and would be a good learning experience even if i can't manage to get it running. Looking online, Colt's didn't seem to quite match the look of my mower, which led me to discover it's actually a 'Super Colt'.

What started off as a simple 'Let's find out why it's not sparking' quickly resulted into a complete strip down of the entire mower and lastly the engine!! Taking plenty of pictures along the way, and bagging up nuts and bolts with labels so as not to forget what went where, I've now stripped the entire thing down so that I'm left with the engine block, and an exhaust that is well and truly welded to the block - thankfully it doesn't appear damaged, just rusty, so It can stay where it is (frustratingly for my OCD).

I'm going to test the waters here to make sure I can upload pictures properly, and once I can, I'll post up a few pictures I've taken during the strip down. I've come across quite a few things I’d really appreciate some advice with so anyone interested in looking/reading can hopefully help me out - which I’m hoping will help others out in future who are thinking of tackling the same sort of project.

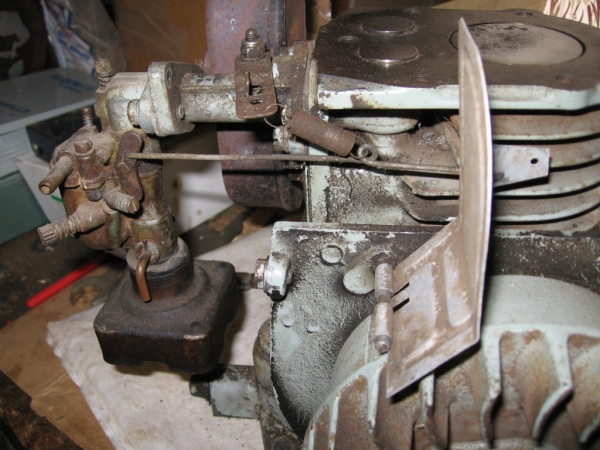

Here is a Picture of the mower after collecting it

Forums

After 8 months and a couple

After 8 months and a couple of days, I finally see the results of your labour of love, a cracking, thorough job and surely the shiniest starter pully I've ever seen, I've been following your progress from the start and like you say, if it wasn't for the knowledge of other club members helping with these restorations, a lot of them including my own probably wouldn't have got completed. Well done.

Well done Clive - whats next

Well done Clive - whats next on your mower after swapping out the broken sprocket? Hopefully those 2 Atcos you recollect are still knocking around somewhere and going strong.....

Thanks Lee, it sure has been a labour of love! I'll have a search and check out your restoration :)

Now I just have the remaining challenge of getting it to run.....

Fresh petrol in the tank - check

Petrol tap open and fuel flowing to carb - check. There is fuel from the carb inlet back up to over half way up the pipe, then air in the hose until the tap - is this normal?

Tickler pressed 2 or 3 times until petrol appears at the overflow hole - check

Choke set at 45 degrees, throttle lever at 1/4 to 1/3 - check

After 3 or 4 pulls I finally had some chugging from the engine :) although short lived sadly... It seems to have a mind of it's own whether it starts, whether it idles, and for how long it idles, before cutting out. I've managed a run of around 45 seconds where it idled beautifully, I could increase the revs enough to engage the blades and then back off again, clutch working very well indeed with good control over blade engagement.

However, It seems completely random as to when it cuts out and whether or not it starts again.

My initial gut feeling is that the coil is hit and miss as to whether it is producing a consistent reliable spark and for how long, as surely if it were down to carb settings, it would be a bit more consistent in terms of starting at least, and then just running rough or mixture settings preventing the throttle from working properly?

I've set the Main jet and the slow running screws to 'get you running' settings which I found online. It seem more likely to start and run at all if i use no throttle, and keep the choke closed. Saying that, sometimes opening the choke makes no difference to the running when it is running, and other times it makes it cut out. All just seems a bit intermittent with no real pattern, which is what makes me think it's the coil. I ended up with a sore shoulder as i must have tried about 20 times in a row to start it towards the end of the experiment, and it just wouldn't kick into life.

Whats the best way to step through this to identify the issue?

The fun you are having trying

The fun you are having trying to get it running smoothly sounds very familiar, unfortunately there's often plenty of trial & error associated with this! As far as a dodgy coil is concerned I don't have much experience with this but I'd expect opening & closing the choke to make a difference to the running anyway. If you suspect it runs better on part or full choke then you need to richen the main jet mixture. Those 'get you running' settings are very much that, it's usually enough to get the engine to start but from there it's likely you'll need to do some fine tuning. Another factor could be how much play is there in the carb butterfly spindle/shaft, as if this is badly worn it can be quite tricky to tune perfectly.

I recall one of my 75cc suffolks displaying similar symptoms after I fitted new rings. Prior to stripping it down the engine was set up well and running ok, aside from the ridiculous amounts of blue smoke! I left the carb settings alone, fitted new rings & cleaned up the valves & head etc. Confident it would now automatically run like a dream, it barely ran at all at first; until I tuned the carb then it was fine!

Got to the stage where it's

Got to the stage where it's really got to be hands on but...

Check that you do have a regular spark over a 6mm gap off the bare end of the HT lead with the plug out.

Open the main jet a turn past the recommended setup setting.

Lightly flood with the tickler

Full choke and ONE pull with just a crack of throttle

Off choke and full throttle until it fires

Hopefully it will run long enough for you to play with the main jet - reduce it bit at a time.

Get that sorted then worry about the idle.

That is beautiful, better

That is beautiful, better than the manufacturer did in the first place, the only problem is you will have to go and purchase a lawn mower because you most certainly cannot use that machine to cut grass.

Regards Geoff

Sunny Australia.

Thanks Geoff! You're

Thanks Geoff! You're absolutely right - I've bought not one, but 2 more mowers - Ransomes Marquises - which I will be restoring and will be hopefully using one of them as my 'actual' mower :)

Hopefully I don't over-restore them and then have to look for another mower to use, and then another.....

Thanks for the words of wisdom Angus and Johnson. I also thought with so much being new/rebuilt, it should just miraculously fire into life and run perfectly. I decided to make the fuel hose a bit shorter and also removed the air from the top half of the hose - just in case this was part of the problem. I squeezed the air up back through the fuel tap into the tank with the tank lid off until the hose was full of petrol. Backed the mixture screw out another full turn as per Wristpin's advice and set the choke on with a tiny bit of throttle. Not expecting it to start it actually fired straight into life on the first pull for a few seconds. Second start, no choke and full throttle, started up straight away as well, and continued to run! Had a good play with the mixture screw while at full throttle to slowly see the effect of closing the screw and opening it, and found what seemed to be a happy medium. Still running after 5 minutes and didn't cut out once! I have tried to adjust the idle/slow running but I think that's going to need some more time to get set just right, as currently it's very difficult to get it to idle at a speed where the blades aren't trying to creep around, and where the revs are too low and the engine cuts out. I'm sure it's just a combination of the remaining two screws - however I could feel the start of some drizzle so rushed it back indoors! Very happy indeed though :) Here's a video for anyone interested

Well done, that certainly

Well done, that certainly looks promising. The engine sounds sweet, no smoke or rattles. It's not easy to explain but where your throttle cable screws into the carb, it looks like it should be screwed in more. When your at what I presume is tickover towards the end of your video, the throttle lever on top of the carb still looks about a third open & it shouldn't be. Wristpin will be able to explain this better than me!

If you struggle I'll try & upload a few pics of mine, but please excuse the vast difference in cleanliness!

I set off looking for a photo

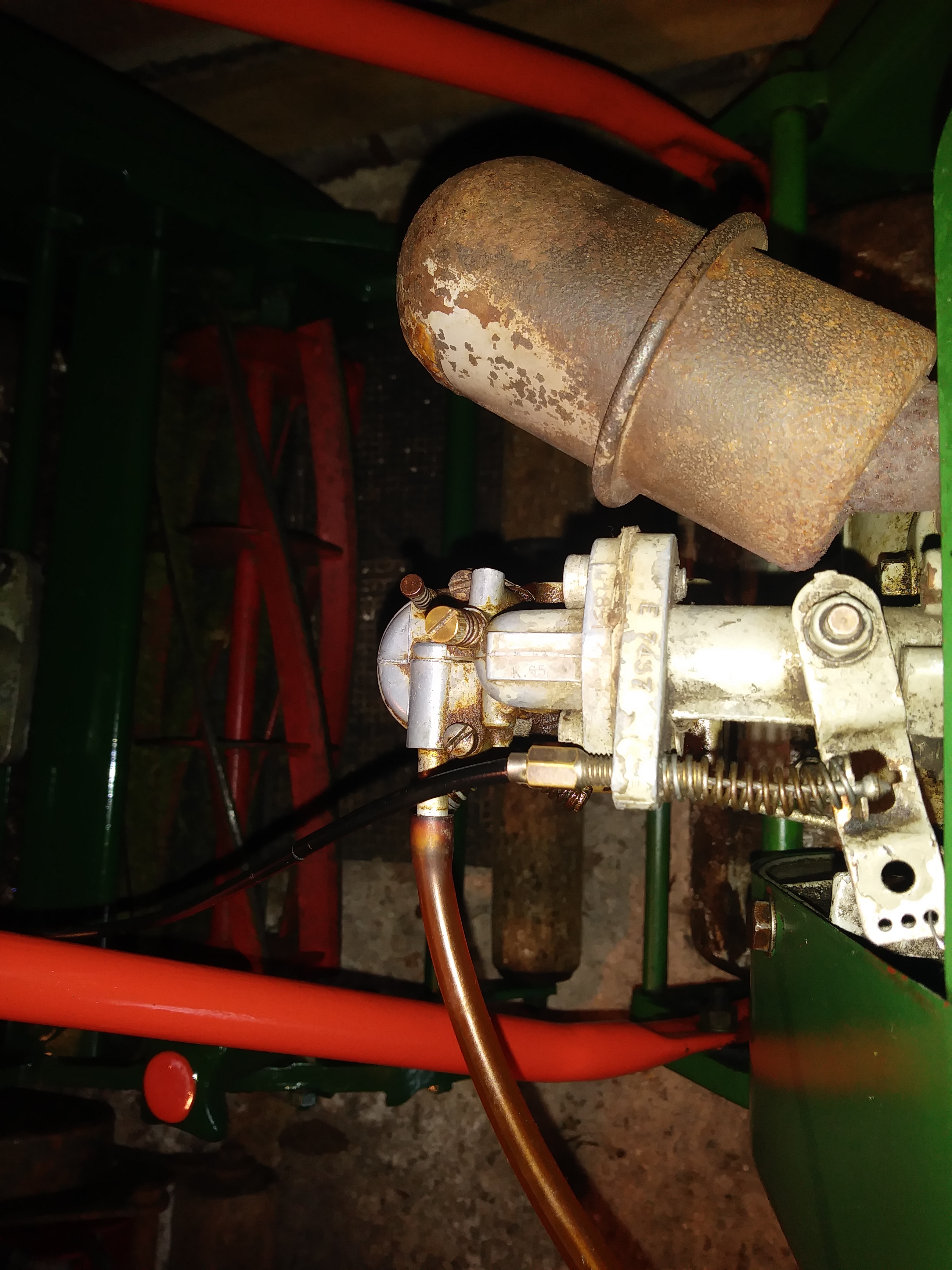

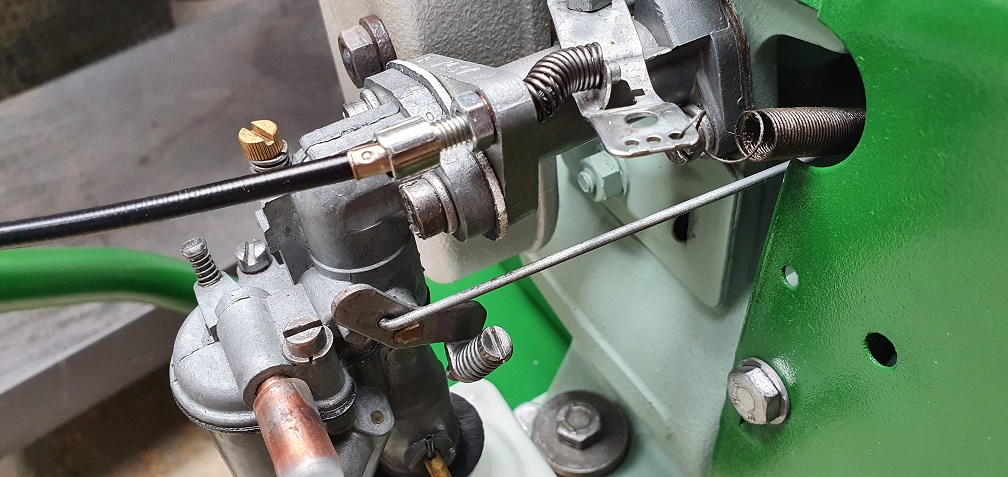

I set off looking for a photo of things at tickover as i recalled taking some a few years ago to help someone out...but hadn't got one showing fully assembled with cable......only these two that show the lever right back as at tickover and the spring relaxed.

C.

Off topic....but oh dear...

Off topic....but oh dear.... this followed me home tonight..... ;)

this followed me home tonight..... ;)

C.

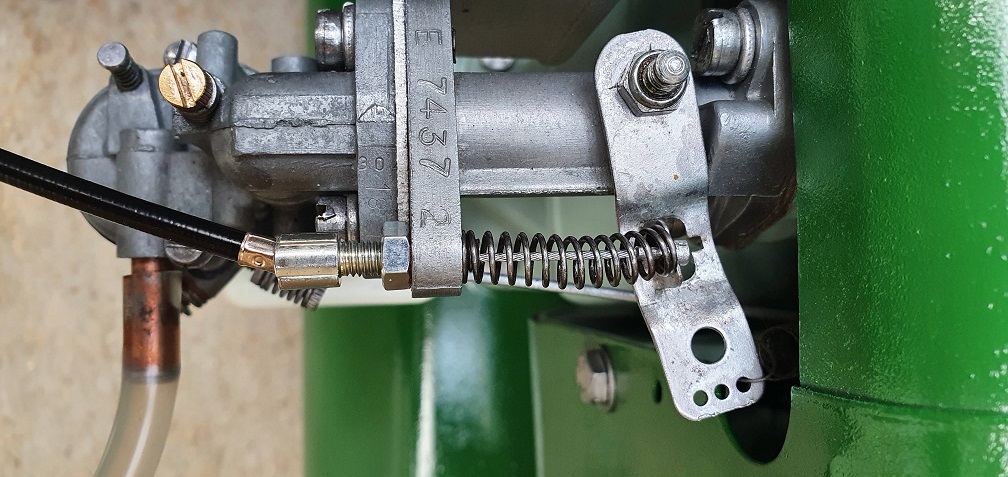

Here's a couple more pics

Here's a couple more pics showing the throttle closed & its relation to the butterfly spindle.

And with the throttle about

And with the throttle about half open.

Apologies for the dirt & grime here compared to your showroom example!

followed me home tonight.....

followed me home tonight..... ;)

Tin deck and Aspera engine, but it’s survived. Not dissimilar from a Suffolk Galaxy? and a pale blue Qualcast.

I set off looking for a photo

I set off looking for a photo of things at tickover as i recalled taking some a few years ago to help someone out...but hadn't got one showing fully assembled with cable......only these two that show the lever right back as at tickover and the spring relaxed

Back in the day I used to find that bending that pivoted relay lever slightly downwards would create just a bit more slack to encourage the throttle to close against the stop screw.

Thank you all for the

Thank you all for the pictures and information, really appreciate that. I see what you mean about the throttle cable ferrule Jonson. Hopefully if the weather over the weekend is a bit better than it is today, I'll be able to get outside and do some fine tuning. One thing regarding the throttle lever position, is that if I have the 'off'' position any further anti-clockwise (looking down on the lever from behind the mower) to the end of it's travel, then the nipple of the throttle cable quite easily falls out of the hole in the side of the lever mechanism. This is why I've rotated the lever around slightly, to prevent this.

For example, if i have the throttle lever in this position, you can see the cable nipple can quite easily pop out

So having it in the off position where I currently have it, means the nipple is pulled round slightly and can't come out.

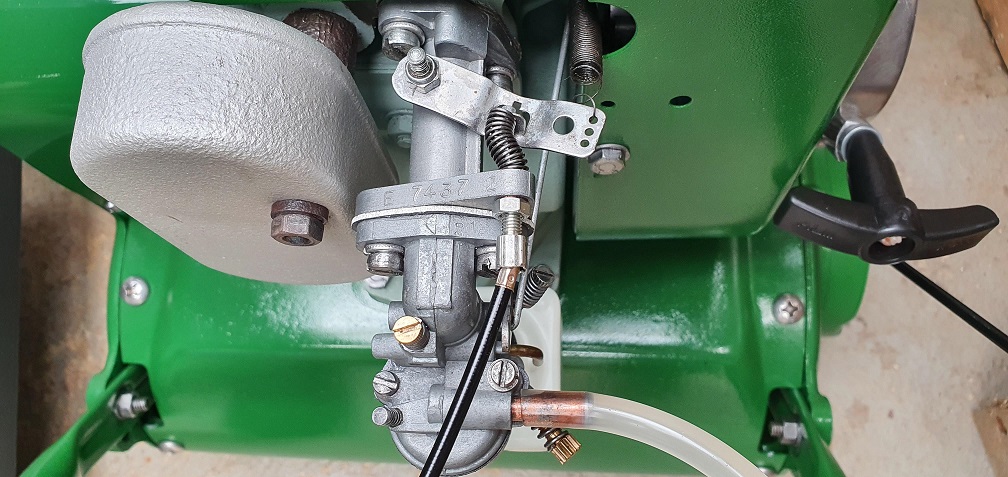

Here is how things look with my current throttle setup:

Throttle closed - pivot lever is as far back as it can go, as it touches the inlet manifold, and the governor spring is fully relaxed

and throttle stop screw is touching the carb body

While at full throttle, this is how it looks

With the throttle closed, the mower slows and then cuts out, so I don't need to use the spark plug grounding plate, but as convenient as this is, I don't think this should be the case should it? Hopefully more adjustment at the weekend will do the trick...

If it stalls every time you

If it stalls every time you close the throttle, try turning the slow running screw anti-clockwise as this will increase the revs. Once you've got the slow running & main jet set nicely then you can fine tune the idle speed with the throttle stop screw. With a bit of practice it's easy enough to get the right balance, have fun tuning!

The slow running mixture

The slow running mixture screw and the idle stop screws need to be used in conjunction with one another. From memory a good base setting for the mixture screw is 3/4 of a turn ( anti clockwise) from fully closed. So set it to that and wind the stop screw in to give a fast idle. Then move the mixture screw about 1/8 of a turn in either direction to get an idea of what that does . Then reduce the idle speed with the stop screw and return to the mixture to find the sweet spot for the reduced rpm . Still running too fast? Lower the speed with the idle stop and repeat the mixture adjustment.

After a bit of that, you should have a disengaged centrifugal clutch and an even tick over .

Thanks very much for the

Thanks very much for the tuning advice. I have followed the above and now managed to get the mower ticking over lovely and smooth and slow enough that the blades are not engaged :)

However doing this has seemingly affected the fast running. Now the engine doesn't run as fast or as smooth at full throttle. If the idle screw and slow running screw have only been adjusted, I don't understand how this could affect the full throttle side of things? The only other oddity remaining is the air lock in the fuel hose. Each time I go to use the mower, and the fuel hose is empty, after opening the fuel tap I have to spend a few minutes squeezing the hose to get all the air up through the hose and into the fuel tank, until the hose is full of fuel, and then it runs happily. I will try putting the carb end of the hose in a jar and see if the same thing happens or not.

Adjusting the slow running

Adjusting the slow running may have a very small effect on running under load. Just open the main jet a tiny amount and it should sort it.

I wouldn’t be too concerned about the air bubble in the pipe, there’s probably a bit of fuel flowing round the edges of the bubble. On some Briggs installations on ride-on mowers the transparent in line filter appears to be empty.

There is definitely a strange

There is definitely a strange issue with the fuel tap/pipe - it's more than an air bubble in the pipe - the top 3/4 of the pipe length is full of air, and once the fuel in the bottom of the hose is used by the carb, the engine starts cutting out. The only way to get it to run properly is to squeeze the hose repeatedly over and over to expel all of the air up through the pipe, fuel tap, and into the fuel tank, filling the entire length of pipe with fuel. Then run the mower and it works fine. Other than that, everything else is now running and working perfectly!

The fuel pipe not being full

The fuel pipe not being full is usual, I would be examining the fuel cap, perhaps it isn't letting air into the tank and airlocking the fuel flow.

The time has come when I am

The time has come when I am going to have to sadly depart with my Super Colt restoration. Having only used it maybe 4 times in total, I'm finding it too difficult to manoeuvre between the front and rear gardens, and with the weight, combined with the awkward angles and steps involved, it's just not practical for our setup here. Having been used a handful of times, the blade has slightly lost it's gloss red 'new' colour, and a small patch of paint around the fuel tank filler has wrinkled due to a couple of drops of petrol, but other than that, it's as per the restoration thread.

If anyone reading this thread is interested, or knows someone that might be interested, please get in touch. I would like to see this mower go to someone that will cherish it and maintain the condition it is in. If I had the space, I would keep it to have it on display.

I will put an advert put into the classifieds on here shortly.

I once went out to a similar

I once went out to a similar machine with running problems, the lady owner had been informed by her gardener that the fuel had to be 'pumped' through to the carb. As I watched, she continually pushed and pulled at the plastic fuel tap until the translucent fuel tube was full! That was decades ago and I've never forgotten it, I usually clean out the tank and often fit a new tap, just to be sure.

We have already been through

We have already been through this, yes it has the wrong grassbox, it should be a metal one, but everything else is correct, because it is an Atco badge engineered machine. They were made for those who had more money than sense, there was a significant difference in price between a Suffolk Super Colt and its Atco version

I mistakenly replied to the

I mistakenly replied to the first page or maybe second, not realising it was an eight pages long posting, was concentrating on the content, not the small print and row of numbers at the bottom!

DJD - no problem, I

DJD - no problem, I appreciate the comments none the less! It was a couple of years ago that I embarked on this restoration and it certainly took me a while, as I was cutting my teeth so to speak! I was only resurrecting the thread for the benefit of any previous followers who may know someone that might be interesting in acquiring this mower, now that I am regrettably having to sell. Eight pages is more than enough to send most folk to sleep, but hopefully it provided a useful reference for images and information on how things go together on one of these popular engines/mowers. A lot of useful know-how and tips from all the contributors within!

Lovely to see these photos :)

Lovely to see these photos :) Good to find the appropriate tap too.

Some slight progress on mine today....The cylinder sprocket that I located on e-auction arrived in the post and is like new :)

Can't remember if I mentioned before on the thread but when I was on YTS at my first machinery employment in the early 1980s I had to take some cylinders over to the sister company in the next big town to get ground quickly for a job...they had the grinding gear for both sites. Up on their racking were two of these Atco, brand new old stock. I was fascinated to see them and was told that they were delivered incomplete, I think they were minus handles or grassboxes?? Anyway, dispute over delivery must have raged on...and there they sat...I often wonder at what stage they were traded on.?

C.