Edwin Budding's Adjustable Spanner Registered Design

Edwin Budding registered a design (No 7213) for an adjustable spanner on 19 May 1843. Registration provided lesser protection than a full patent. It is not known why Budding chose this option. It is possible that that the cost was a factor because registration was likely less expensive as research and legal fees would have been lower. It is also possible that Budding did not foresee the need for a full patent or that it was not possible for some other (legal) reason.

Budding's design featured a worm mounted along the back edge of the spanner that could be turned by a finger or thumb to adjust the gap of the jaws. The spanner was initially manufactured by John Ferrabee at the Phoenix Ironworks in Stroud and at The Earl of Ducie's Ironworks in Uley (Ferrabee took on a lot of the products from the Uley Ironworks after it closed). Some of the early examples have the name "Edward Budding" stamped on them and it is assumed that Budding was using this name instead of Edwin at the time for some reason.

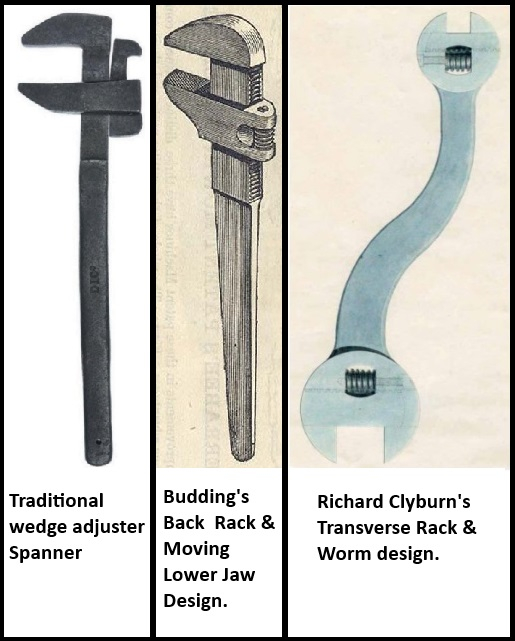

Richard Clyburn, who knew Edwin Budding, worked at The Earl Of Ducie's Ironworks at Uley and came up with a similar design shortly after Budding. This had a worm fitted into a gap in the body of the spanner between the fixed and moving jaw. As with the Budding design, the spanner was adjusted by turning the worm.

Both designs were well known at the time and are still recognisable today. Catalogues and brochures issued by ironmongers and retailers as late as the 1890s - and possibly later - referred to these spanners as "Budding" or "Clyburn". In general, modern spanners based on the Clyburn design are more widely seen in everyday use whereas the Budding design (also referred to as an "English key" in the past) perhaps has more in common with the modern "pipe wrench" or "Stillson".

Prior to these innovations, adjustable spanners were available but these had a small wedge that was inserted between the body and moving jaw. This made it difficult to set the spanner to a precise gap and also meant the jaw could move if the wedge were dislodged for any reason. Both Budding and Clyburn's designs removed these limitations.

World expert and leading collector on the adjustable spanner, Ron Geesin, wrote:

BACK RACK AND WORM (MOVING LOWER JAW) [Buddings design] the other, and slightly less, revolutionary mechanism to Clyburn's TRANSVERSE RACK AND WORM, usually called THE BUDDING or BUDDING PATTERN after its inventor, Edwin (Beard) Budding. This was based on the SIMPLE WEDGE type where the wedge was replaced by a rack and worm mechanism, only made possible by the more sophisticated machinery developed within the Industrial Revolution. The upper jaw was formed at right angles to the main shaft/handle which had a rack formed along the upper half of its back. The lower jaw extended from collar riding on the main shaft. The back of the collar held a worm adjuster corresponding to the rack on the shaft, usually running on a dome-headed bolt. True '1st Generation'

BUDDINGS, made in Ferrabee's Phoenix Works, had the shaft/handle tapering slightly towards their ends, whereas the '2nd Generation', made in hundreds of thousands in Sheffield and Birmingham, usually had no taper.