Books About Mowers

| Book Image | Body | Order Now | |

|---|---|---|---|

| A Little History Of British Gardening |

|

Order Now | |

| Antique Garden Tools & Accessories |

|

Order Now | |

| Antiques from the Garden |

|

Order Now | |

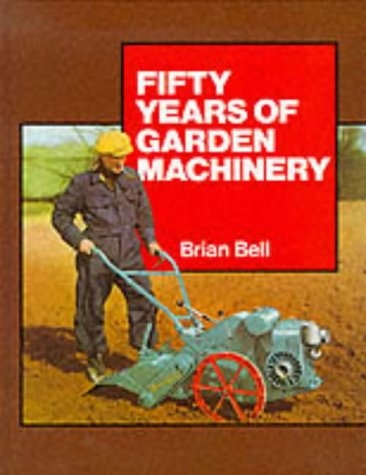

| Fifty Years of Garden Machinery |

|

Brian Bell looks at garden machinery in the second half of the 20th century. Includes information about lawn mowers during this period. |

Order Now |

| Garden Heroes & Villains |

|

Order Now | |

| Garden Tools |

|

Order Now | |

| Glossary of Gardens |

|

This is another title in the popular Shire Album series. |

Order Now |

| Hand, Horse & Motor - The Development of the Lawn Mower Industry in the United States |

|

Old Lawnmower Club member Jim Ricci, a resident of Massachusetts, has published a new book on the history and development of the lawn mower in the USA. This is the culmination of decades of research by Jim, who first joined the Old Lawnmower Club in the mid-1990s. The book has over 250 pages and more than 150 images of American mowers going back to the 19th century. Jim is an active member of our club and regularly attends our Annual Rally and other events in the UK. |

Order Now |

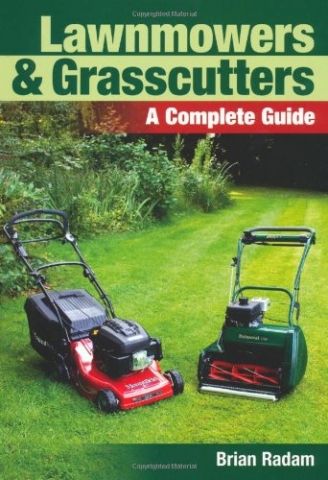

| Lawnmowers and Grasscutters: A Complete Guide |

|

This book, published in 2011, is by OLC Member Brian Radam, so we definitely recommend it. This book can be ordered by Club Members from the Club Shop. |

Order Now |

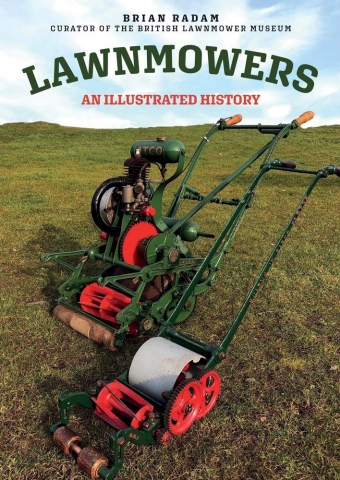

| Lawnmowers: An Illustrated History |

|

Club Member Brain Radam takes a closer look at the history and development of the lawnmower. This book can be ordered by Club Members from the Club Shop. |

Order Now |

| Mervin the Magic Mower Series |

|

A series of beautifully illustrated stories for children. |

Order Now |

| Miller's Garden Antiques: How to Source and Identify |

|

The latest Miller's Guide, with a small section on mowers but mainly covering garden tools, furniture and ornaments. |

Order Now |

| Old Garden Tools |

|

This is an excellent but inexpensive introduction to collecting garden tools of all kinds, including lawn mowers. |

Order Now |

| Old Lawnmowers |

|

David Halford's book was probably the first dedicated to the history of the mower when it was first published in 1982. For many members of the Old Lawnmower Club this was their introduction to the subject. We've all learnt a lot more since but you can do a lot worse than this excellent little book from Shire, the UK's specialist publisher of books about bygones. |

Order Now |

| Ransomes Sims & Jefferies: Agricultural Engineers |

|

Brian Bell traces the history of this famous Ipswich based company from its pre-lawn mower roots to the present day. Includes information on the mowers produced by the company and many images. |

Order Now |

| Seventy Years of Garden Machinery |

|

Enlarged and updated version of Brian Bell's previous book Fifty Years of Garden Machinery |

Order Now |

| The Forgiveness of Nature: The Story of Grass |

|

Graham Harvey tells the story of grass and the lawn. There is a chapter on the mower and the Old Lawnmower Club. |

Order Now |

| The Garden: An English Love Affair: One Thousand Years of Gardening |

|

Order Now | |

| The Grass Is Greener |

|

Tom Fort writes about lawns, mowers and his memories of a Dennis mower while growing up in the 1950s and 60s. There is a whole chapter about the Old Lawnmower Club and some of its more colourful members! |

Order Now |

| The Lawn Expert |

|

Apparently this is the world's best-selling book about the lawn. It's not about mowers or their history but it's still a very useful book for anyone with even the smallest lawn to tend. |

Order Now |

| The Lawn Mower Manual |

|

Old Lawnmower Club member Brian Radam wrote this book in the popular Haynes mechanics' series. This book can be ordered by Club Members from the Club Shop. |

Order Now |

| The Lawn: A History of an American Obsession |

|

This book tells the American story of the lawn. Mowers are, of course, featured. |

Order Now |

| The Story of the English Garden |

|

Published in 2018, this book covers the history of the garden in England. |

Order Now |

| Two Men Went To Mow |

|

Club member Clive Gravett has written a book about Edwin Budding and his own passion for mower collecting. This book tells the story of this world changing piece of machinery which has impacted on all of our lives. |

Order Now |

| Walk Behind Lawn Mower Service Manual |

|

This is for users of modern mowers but if you've ended up on this site looking for information on how to maintain your everyday mower, this could be just for you! |

Order Now |