Suffolk Punch Starting and running problems

I have done a complete strip and rebuild of Suffolk Punch 98 engine with Zenith TCA carb. Valve lash checked and correct, spark plug gap correct.

Initial set up is with slow running jet opened 1 turn, main jet opened 3/4 turn. Tickler depressed til fuel overflow, strangler fully closed and approx 1/3 throttle open.

After a couple of pulls, the engine started, ran for 2 or 3 seconds, then died. Repeat and the same. Then tried varying throttle and strangler, started with full throttle, ran for about 5 seconds, then died.

So, I can sometimes start the engine, but cannot find a setting that will allow reliable starting and then steady running. I have searched the forum and tried many tips, but am struggling to solve this one and have fallen into the trap of altering too many variables out of frustration, I then get tired pulling the cord, lose my temper, curse the mower - you know the script....

So I need some advice please - is there a systematic approach to set-up etc that will allow me to step through the issue and get this running?

Forums

Thanks for the guidance. To…

Thanks for the guidance. To answer your points:

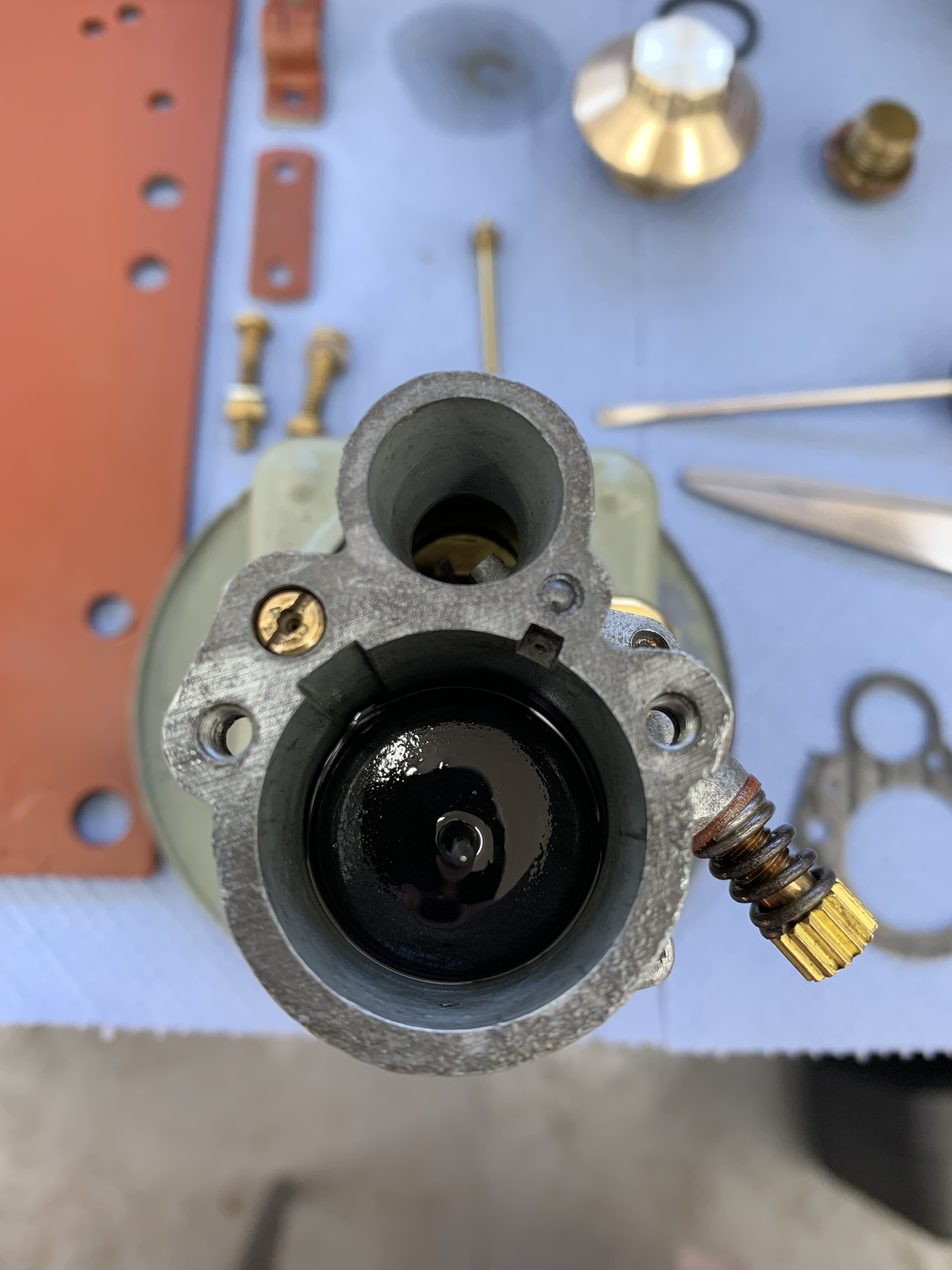

Main jet screw pictures attached. The point of the screw does look worn - would appreciate a more expert eye on this. I can order a replacement if deemed necessary.

Float and needle are brand new. I am confident this is sealing correctly as there is no fuel overspill unless I depress the tickler and then wait for fuel to leak from the overflow hole.

I'm not sure how to check if the governer is correctly set-up. Would appreciate some help with this, so I can check.

I've not done anything with the gasket yet. I'll see how I get on with feedback from the above points so that I'm only changing one thing at a time.

In my opinion; that groove…

In my opinion; that groove in the adjusting needle would cause slight fluctuation on tick over,

And I would suggest replacing and check No. 21 the slow running tube for blockages.

The regulation of fuel through jets and tubes is crucial, so overkill cleaning with drill bits and abrasives can cause overfueling, so best to change all these.

The engine naturally should start with the choke lever horizontal and after a few seconds go to the vertical 6 o'clock position. Running on choke or between choke and the 6 o'clock position certainly points to carb. issues.

regarding the fan governer, it should like a mechanical Governer, when faster air flow is achieved through higher revs, actuate precisely through the rod linkage on the carb butterfly.

The Suffolk engine, like the Villiers MK7 has a blower vane governor, which if set up right is fit for purpose.

Sometimes the butterfly is worn in the pressure die cast case, as in a lot of well used carbs, and often we re-bush or replace, but this is because Dad & myself like everything right and start on first pull.

After Carb. is checked over for float bowl leaking, etc... if problems persist, you would need to look at the ignition, and others.

Thanks again for the…

Thanks again for the feedback - I'll replace the adjustment needle.

The slow running tube was cleaned with carb cleaner and compressed air blow through only. I also verified it wasn't blocked on refitting. No abrasives used at all on any of the carb components, but I can't know if it has ever been cleaned prior and with what. The throttle butterfly was replaced new.

I'll report back once I have replaced the adjustment needle.

So an update - I have…

So an update - I have replaced the adjustment needle as a first step. Engine started easily enough but died again after a few seconds running. Couldn't then get it running again, but noticed the spark plug was wet - probably from the additional attempts at starting? But possibly also over-fuelling.

I didn't replace the slow running tube, so i'll do that next. The carb has clearly been pulled apart before so I have no knowledge on how this tube was cleaned etc beforehand.

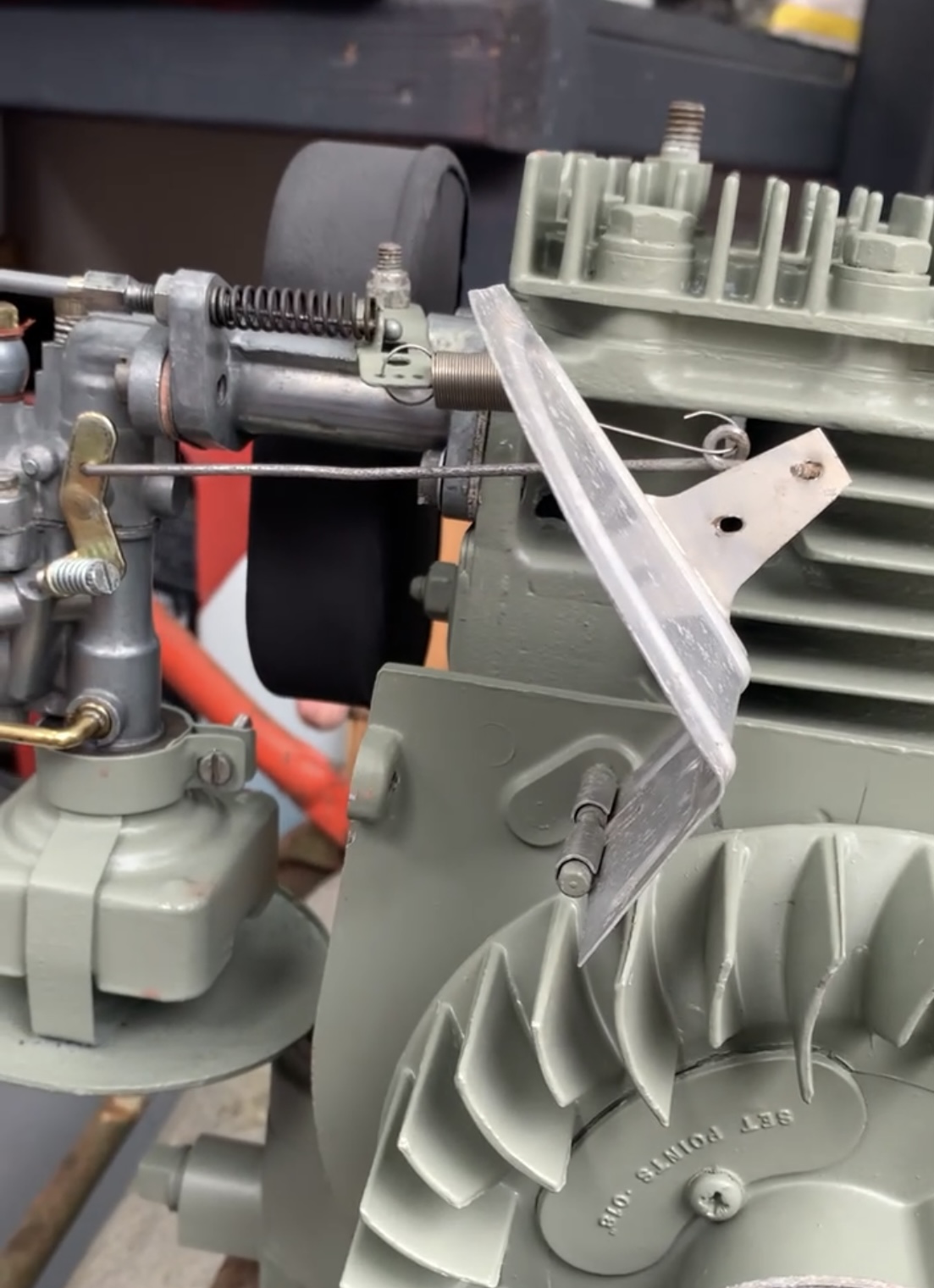

Is there any preferred set-up for the governer blade? It's currently connected as per the pic below.

I haven't seen a Suffolk…

I haven't seen a Suffolk Manual for Years, so wonder if it says in that on the vane governor default settings.

Anyway, from previous experience, I can say, that I see of the three hole setting for the spring on the throttle arm, you have it on the most tensioned, so when the air blows, the spring is already weighting it to retard, as naturally the fan will move with the airflow.

So to at least get in running constantly, without stopping, albeit fast tick over or more, screw out the screw on the throttle butterfly, as you will have noted from testing and observing this is the idle adjuster.

Indeed one think you can temporarily do to test is disconnect the governor rod with the idling screw screwed in, (ie. away from the body) so if it runs , Or temporarily put a wedge or clothes peg under to stop butterfly retarding as I say, quite fast, and doesn't stop, we can deduce the governor vane may be cause of the said issues.

So as I say, you have the spring in the most retarded throttle position, so naturally you can experiment with the three hole positions on the arm. of then the spring gets stretched, but I see you have fitted a new one.

Then there is the two setting of the vane, I would put back as found, as without seeing the book, or looked at one of these for years, cannot remember.

I note a baffle under the air filter, I cannot remember ever seeing this fitted, but looking at it, there seems plenty of gap between it and the air cleaner gauze, so don't think that this would be a problem.

As I say, other Suffolk owners with recent experience may be able to advise.

OK, it's been a while…

OK, it's been a while updating. I have done a couple of things and still cannot get the mower to start and remain running.

I've removed the governor from the engine which hasn't removed the running issues.

I've sourced a replacement slow running tube, only to find they are different in that my old tube screwed into the carb body vs the new one doesn't. I've got a query with the mower centre as to whether this is a known change or a previous DIY effort.

Secondly, when I removed the carb bowl, I noticed some fuel staining across the gasket. This tells me a poor joint, leaking, hence contributing to or causing my issues?

As always, appreciate your thoughts on this. I'm tempted to source a recon carb that has been bench tested to see if that improves things.

Is it gasket staining? It…

Is it gasket staining? It looks like the stamped gasket paper logo?

Overtightening the two screws that hold the float bowl onto the carb. top body can cause distortion to the pressure die cast components

As per previous, lapping the faces with say 250 - 400 grit emery on a perfectly flat surface will remove any chance of air induced to the mixing bowl or fuel escaping

Aaah yes - think you're…

Aaah yes - think you're correct there with gasket printing. Somewhat embarrassed now, but every day is a school day. I'll lap the paper as you suggest. Sadly running out of ideas now, but will keep plugging away.

It runs! In the end I was…

It runs! In the end I was running out of ideas with the carb, so sourced a recon from eBay. Swapped them over and the engine fired up and happily ran until there was no more fuel left.

So I don't know what isn't right with the original carb I stripped and rebuilt so I will try and find out.

But good news in the end!

Could be a number of things…

Could be a number of things, so look at each mentioned to see if that improves:

If you are confident you have followed the Carb. refurbishment & setting adjustments, and the needle jet isn't worn or bent, it could be a mixture of things.

So on carb, just check:

No. 11 the adjusting needle not bent or worn,

No. 8 the float bowl needle seat & associated float No. 10 if not sealing when float chamber full,

causing over-fueling.

No. 9 the gasket not sealing, I always rub the mating faces on very fine emery on a metrology table in a regular pattern, to ensure faces seat right when refitting.

The air vane governor is not set up right.