Qualcast Classic Petrol 43 Clutch/Roller adjustment

Hello all,

Hello all,

I'm just hoping for a bit of technical advice from the experts please.

The roller on my Qualcast Classic Petrol 43s goes round when lifted off the ground, but when bearing its own weight it won't propel the mower.

Everything else, blades etc., works fine.

I've played around with the clutch adjustment screws to no avail.

I'll try to attach a couple of photos. I'm wondering whether the small gap between the end of the roller and the plastic end disc/cap might have something to do with it?

If anyone has any bright ideas that will save me pushing it up and down my lawn, I'd be very grateful!

Thanks in advance.

Forums

I think that the belt looks

I think that the belt looks slack because it is out of drive and that the problem may be more serious. The large pulley drives a reduction pinion that then drives a ring gear within the circumference of the roller. The mesh between those two can be a problem area, so further investigation may be necessary. The pulley and then the pinion can be removed reasonably easily from the exposed end in your images .The state of the pinion teeth will give an indication of what may be amiss. Be aware that across the Model and time of manufacture range there have been pinions of different tooth count and material , so if a new one is required it is important to identify the correct one from the relevant parts list.

Edit

Just an after thought, although you say that everything else is ok, just check the coupling between the engine and the top shaft that drives both belts. Remove the cover and check the security and condition.

Excuse my ignorance but is a

Excuse my ignorance but is a toothed belt correct for the drive on that mower ? Thanks

Toothed belts are often used

Toothed belts are often used in small diameter smooth pulleys as they cope with the small radius and clutching function better than a full V.

Thanks for all your thoughts.

Thanks for all your thoughts. I'll take a look and report back. I suspect that it may well be to do with a slack belt.

suspect that it may well be

suspect that it may well be to do with a slack belt.

That could be, but I understood you to say that you had tried that !

I would think it should be

I would think it should be fairly easy to find out where the problem lies. Start the engine with the machine on a flat surface and engage the rear roller drive. If the pulley goes around but the machine does not move, then it is something inside the rear roller drive. If the belt slips around the rear roller drive pulley, then it is likely to be the belt.

Thanks all again.

Thanks all again.

I'm at the point of trying to remove the roller in order to inspect the internal teeth etc.

I've removed the drive pinion, pulley, spindle nuts from each end, but now I'm a bit stuck. At the height adjustment end, the roller spindle drops out of a slot in the chassis, but at the drive end it sticks out of a hole, and I can't push it through, try as I might. I think that I must be missing something, but I'm reluctant to try anything too adventurous, lest I pass a point of no return!

Can anyone offer me any guidance as to how to remove the roller please?

Thanks in advance

If I'm looking at the correct

If I'm looking at the correct parts list there's nothing to suggest that once the shoulder of the right hand end of the shaft is clear of the slot, it should not push through at the left hand end and release together with the roller. Try replacing the nut a few threads to protect the shaft and giving it a tap or two with a soft faced hammer or via a block of wood.

The shaft won't come free of

The shaft won't come free of the roller without removing the circlips.

The shaft won't come free of the roller without removing the circlips

Correct, but I think that the OP’s stated issue was that he couldn’t get the roller and shaft out of the chassis.

It’s not unknown for there to be enough wear / movement between the roller beatings and the stationary shaft to cause meshing issues between the pinion and ring gear, but to be enough to cause a loss of drive it would be visually obvious once the pinion was removed - without needing to go further.

Thanks for that. Are you

Thanks for that. Are you suggesting that I should be able to diagnose from the condition of the pinion teeth, without removing the roller? If so, I can try to post a photo of the pinion later for your thoughts.

I'd already tried putting a nut on the spindle and trying to tap it through the chassis with a hammer, to no avail. If I absolutely need to remove the roller in order to diagnose, then I'll give it another go.

I've removed the drive pinion

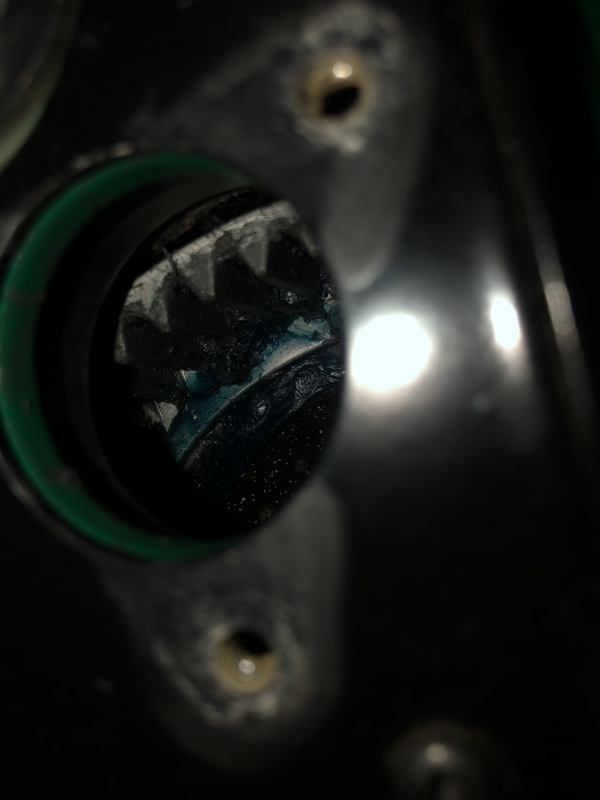

So with the pinion removed you can eyeball the state of its teeth - post an image . For there to be little or no drive due to the pinion any wear of the teeth will be fairly obvious. Also with the pinion out of the way you should be able to take a squint at the ring gear.

The other thing to check for is wear between the roller’s bearings / bushes and the shaft; although wear in that area usually results in the roller jamming rather than loosing drive.

Thanks for your patience.

Thanks for your patience. Please see attached photos. Any thoughts please?

Many thanks

I'll try again...

I'll try again...

There should not be any

There should not be any grease on the nylon of the pinion....

If clean both sides and make new photo's we should be able if they are worn.

Hopefully these are more use

Hopefully these are more use

Hopefully these are more use

The teeth on the pinion look

The teeth on the pinion look good enough . Refit the pinion, lift the rear roller and turn the pinion shaft by hand . Does the roller turn? . No excess up and down play in either pinion bush or roller on its bearings?

If you push the mower the pinion shaft should turn - if it feels smooth and doesn't jam that would seem to be ok. If so refit the pulley and belt

As Hortimech said start the engine and with the cover off does the roller then turn when larger lever pulled up to handlebars?. Does the cutting cylinder turn ok when the red trigger is engaged and smaller lever pulled ?

Please report back - its not the best drive system but normally ok on the smaller width machines

Thanks. Please see the info

Thanks. Please see the info in my original post. Do you need more info than this? If so, I'll take a look tomorrow.

Sorry missed your comment

Sorry missed your comment about the cutters.

Although not visible in your photo there is a small spring at the end of the roller and cutter drive cables where they connect to the idler pulley, With the engine off it should be seen that the springs are extended when the operating levers are pulled up to the bar . It they are, there should be sufficient tension in the belt to drive.If not undo the locknut and screw the cable adjuster on the lower cable out a bit at a time.

One other thing - take off the top pulley nut and check the 2 pulleys still have flats to engage on the clutch shaft. The pulley and possibly spacer in between will pull off the shaft.

Hi, I don't know much about

Hi, I don't know much about this model but the drive belt looks a little slack - even though the clutch is not engaged it still looks a bit loose, maybe stretched a little ? It looks like it's just tight enough to turn the roller when under no load but slack enough to slip when under load. Is there any belt adjustment ? If not a new belt may help. I don't want you to buy another belt if this one is ok , perhaps someone else had an idea. Sean