Bent Crank

Morning

ive actually posted this before but I've now learned that my bent crankshaft can be straightened has anybody tried this. Heres what happened.

My knowing won't change anything but I'm curious!

Rebuilding the MK 6 the crankcase bolt holes won't line up and turning the crank moved the two case half's in different directions! I put the crank between centres and yes, it's bent. The top end wasn't seized and I don't remember a struggle to part the crankcase, the holes are so far out of line it surely would have been. So what's happened?

Forums

As per Hortimech’s answer.

As per Hortimech’s answer. Typically happens when someone “gets rough” with it when dismantling and struggles with undoing the flywheel or the drive dog on the opposite end. Most of the old Villiers books have illustrations of cranks between centres or in V blocks with a couple of DTIs set up.

Well not quite a £1000 job

Well not quite a £1000 job but it is £165 of a job. I do recall having to give my pulley drawer a wack to free it up. Apparently that can be enough. Villiers Services can do it, £40 if it's just alignment or £165 if it requires new pin and rollers. Was looking out for an EBay find but I guess there's no guarantee it would be any better than mine. Bite the bullet time!!!

I've done lots of BSA Bantam

I've done lots of BSA Bantam and Tiger Cub cranks, rebuilt them with new bearings in my press etc. you can use a lathe between the centres too, it's an acquired knack really, but can be leaned, once the basics are understood.

I use a Thor copper headed hammer of about 2lbs in weight, some are a very tight interference fit and need quite a lot of walloping to get right.

Morning

Morning

really interesting and helpful info once again. My thoughts thus far is I'll probably need it reconditioned with new rod, pin and rollers because the fact that I was able to separate the crank without the having a press suggests that the interference fit has been lost, maybe from being separated too many times before I acquired it. If I'm right then putting it back as is it won't be tight enough. In any case to attempt the re alignment process I'll need to invest in some expensive equipment costing more than the recon itself, which incidentally is more than the Standard cost in the first place, that's not going to surprise anybody I know and a very early lesson I learned was don't start a proper restoration project if you're not prepared to spend until it's finished

I've just re-ordered some 1/4

I've just re-ordered some 1/4 X 1/4 and 3/16ths X 3/16ths big end rollers from Villiers Services for some bike big ends, but they are of course useless if the con. rods or crank pins are also worn, but sometimes I strip a crank out and replace the rollers anyway just to give the assembly a few more thousand miles life before a complete new set of working parts is needed, often a new crank complete is cheaper. Bikes are a bit different to mowers of course though, many thousands were renewed each year in the 50's, 60's 70's etc. by such folk as Alpha Bearings at Dudley etc.

Some pics on here may just give us a clue or two as to possibly known courses of action on certain engines, I am not a Villiers expert but I find interest in most machines.

if you go about it in the

if you go about it in the right way you can straighten cranks with V blocks and a fly-press, along with careful use of a dti. I have not done this myself however

Well I watched a lot of

Well I watched a lot of videos of very elaborate test rigs etc and was about to invest in the equipment. Then I got to thinking, there must have been tens of thousands of Villiers rebuilt with cranks not perfectly true and without having the crank even checked. If the shafts weren’t separated and it turned freely on assembly I’m guessing that was good enough. So I decided to try this.

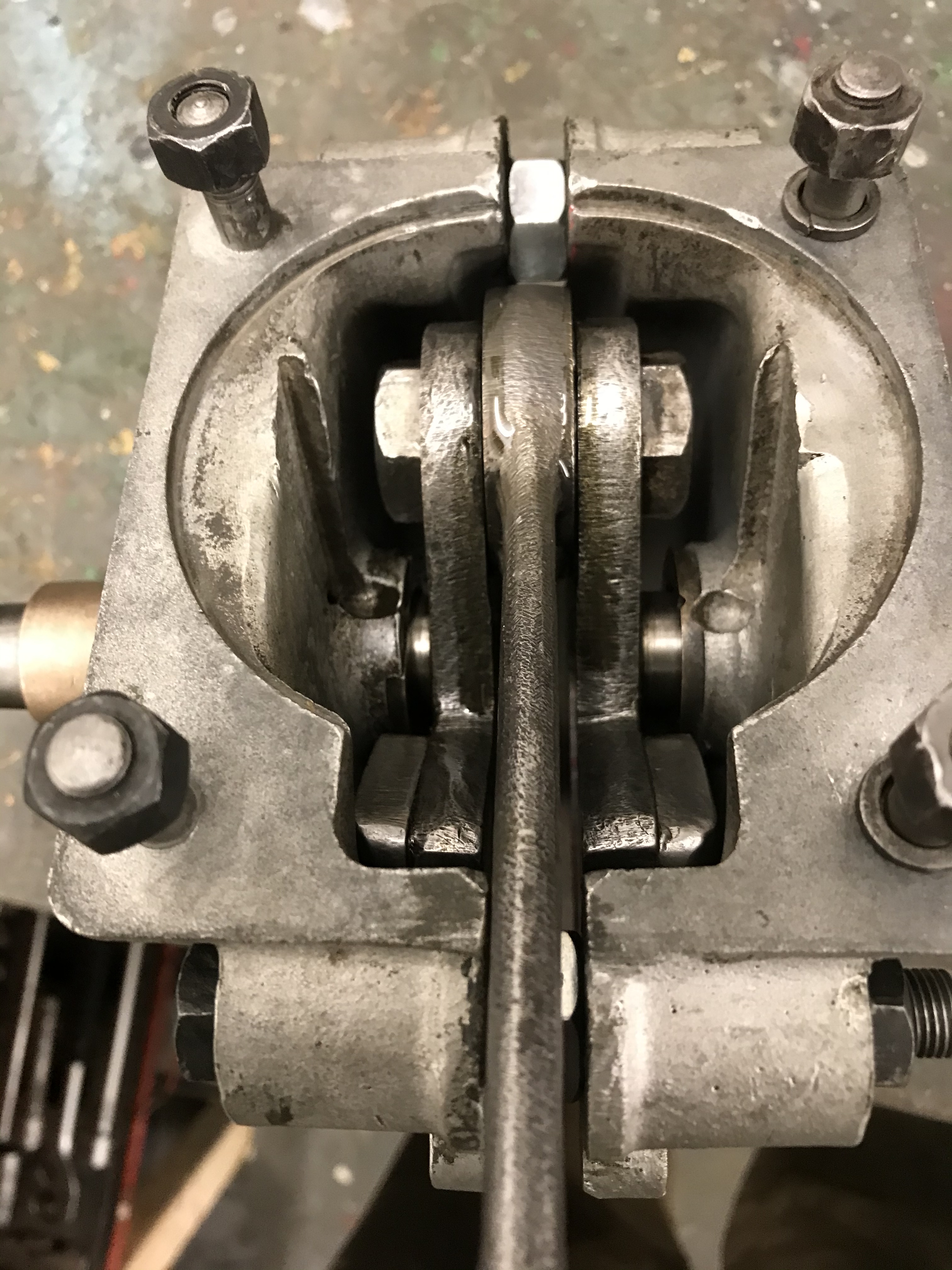

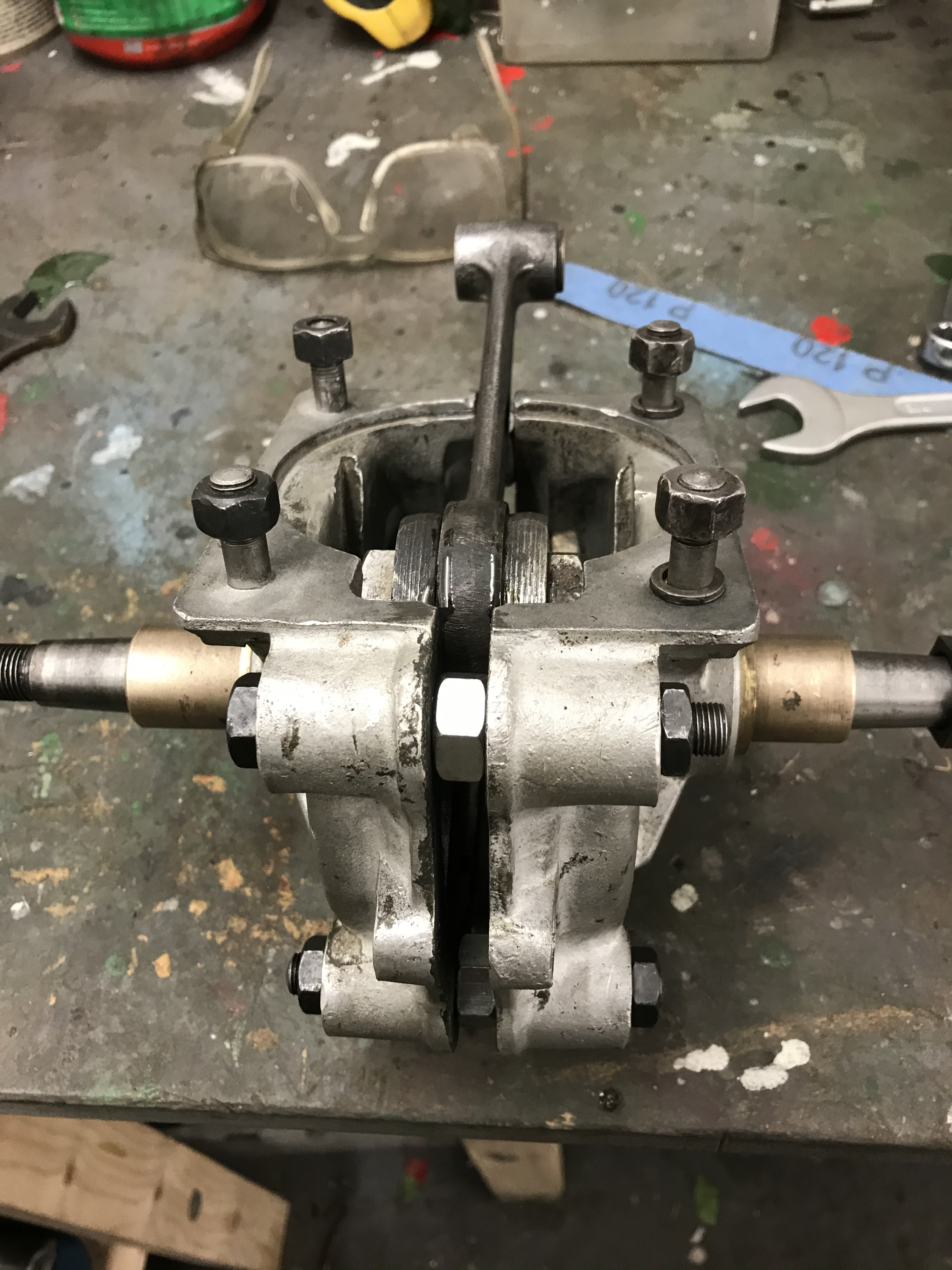

I assembled the crank LOOSELY using original rod and rollers, they measured and looked fine. I then put the crank into the case and assembled it fitting spacers between the two half’s. ( pic below) This allowed access to the two finger tight nuts on the pin, obviously the crank turned freely and the two half’s aligned themselves perfectly. I then slowly tightened the nuts bit by bit ensuring the crank was free at every adjustment. When I thought I’d engaged the two half's sufficiently I carefully nipped the nuts up a little with a spanner disassembled, pressed together, tightened nuts and centre popped nuts and shaft. Rebuilt, perfect!!! At this point I think I’m back to where I started. My only reservation is the interference fit on the pin, is it tight enough after separating and rebuilding? I’m going to give it a try on the basis it’s not going into service but will be a display machine, fingers crossed

Well done for thinking your

Well done for thinking your own way out of a problem, I don't know the model so wouldn't have been able to comment in any but vague terms, a picture saves a thousand words they do say.

This is a 'built' crank i.e.

This is a 'built' crank i.e. two separate webs held together with a pin (on which the big end runs). It sounds like it has been knocked out of alignment and so it needs to be trued again. You need to 'hit' one of the webs, though this is one of those £1000 jobs, £1 to strike the blow and £999 for knowing where to strike the blow.

It might be better if you can find someone who repairs motorcycle crankshafts.