Atco Standard 16 Renovation - Ignition

Just as I feared in my original posting, my ignition coil had failed (no continuity in the secondary winding checked with a multimeter) and like others was dismayed at the prospect of spending some £70 on a replacement 1030 ignition coil. Investigating further I came across reports of others using one of the far cheaper and no doubt inferior M1361 ignition coils available from around £25-£30.

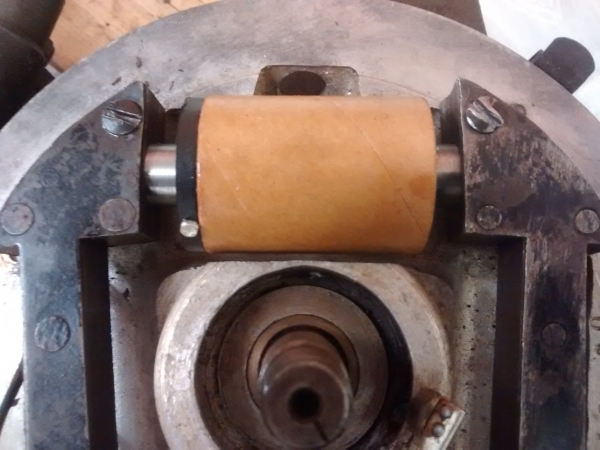

The problem is that the M1361 coil has a smaller core diameter (10.9mm vs. 14.2mm) and is shorter (74.3mm vs. 89.1mm), also the windings themselves are narrower (50.7mm vs. 66.5mm). Fortunately I have a small lathe and was able to make up two small adapters to enable this smaller coil to fit snugly between what Villiers describe as the laminated cheeks. These were simple to make, I am not a skilled lathe operator.

I am pleased to report that this cheaper coil works just fine and produces a good healthy blue spark. I’m quite sure it won’t last 100 years like some of the original Villiers units and if it fails shortly I’ll be disappointed but at least not greatly out of pocket. And if it does fail I’ll simply push the mower into the garage, it’s not like I’m going to have to call the breakdown recovery service and be trailered home!

I’m aware that it is the perceived wisdom to replace the condenser (capacitor) when fixing ignition problems. I did not replace mine as condenser problems were never a significant problem on the many Villiers engined lightweight motorcycles which used similar condensers. Indeed, our own Villiers Magneto Rebuild article states these condensers rarely fail. This is not saying of course that they never do but when they do fail they tend to do so when they get hot, allow them to cool down and they work again, thereby providing some notice of a need for replacement.

The other small modification I had to make to this replacement coil was to carefully solder on a larger terminal, made out of a small piece of brass sheet, to the HT lead connection to ensure the spark plug lead made good electrical contact.

Forums

Yes, a nice solution to the

Yes, a nice solution to the undersize problem.

There's a caution mentioned elsewhere regarding soldering onto the HT connection as there's a chance that the heat will cause the internal connection to come adrift, thereby ruining the new coil.

Re condensers, I'm with wristpin. Easy and cheap enough to replace at the time when the magneto is in pieces.

That’s a good fix for the

That’s a good fix for the coil pole pieces . I know of a couple of others who have done the same with similar success. Your condenser experience is contrary to mine - possibly because I always do a proper condenser test when ever I’m into a flywheel mag as an insurance against the “ you’ve just serviced my engine / mower , and.... ) scenario . The cost of a condenser being low compared with the labour time for having to go back into the mag again.