Villiers 150cc Lightweight - valve grinding/adjustment

I've got a problem where the plug keeps fouling, with a black/oily residue.

I thought it was running too rich, so replaced all the jets and needles etc in the carb, lowered the slide needle to it's lowest, and ran without the gauze air filter. But it's still doing it (maybe not so often).

I read somewhere that a lot of problems with these engines can be due to the valves (clearances or grinding needed?).

Can anyone please explain how to grind and set the clearances? I've seen the fiche but don't see any way of adjusting. I'm more used to adjustable tappets or shims on motorcycles! Or am I barking up the wrong tree? The piston doesn't appear too slack in the bore, so I don't think it's letting oil past the rings.

Apologies if this question is answered somewhere, I have tried searching first - honest!

Thanks!

BTW what's the recommended oil for these mesh/wire-wool type air filters? Seems to me that SAE30 would be too thick - maybe I should thin it?

Forums

To grind the end of the valve

To grind the end of the valve accurately, I used my pillar drill to make a hole that gave the valve a snug fit into the small 2" X 2" block of pine. With valve sticking out a few thous, I simply rubbed it back and forth on my oilstone, not grinder.Doesn't take very long.

Thanks all, I'll take a look

Thanks all, I'll take a look next week, breather first stop.

Oil leakage around the guides makes more sense than leaking valves. Are the guides replaceable?

Yes, the guides can be

Yes, the guides can be replaced but whether they are still available is questionable. Try Paul Child at Meetens. Bear in mind that there will be wear in both the valve stems and the guides.

Only just got round to…

Only just got round to investigating the crankcase breather!

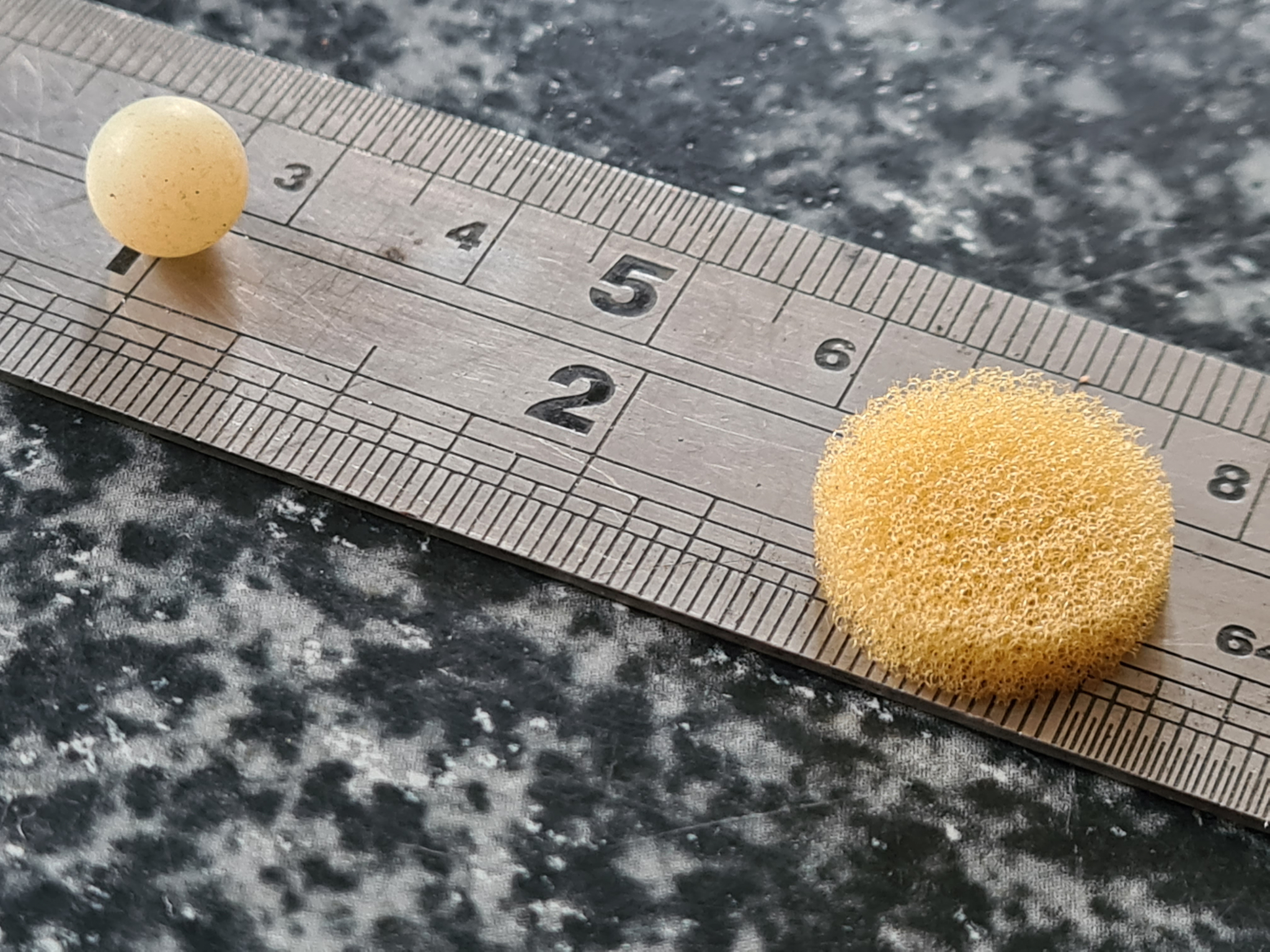

I have been sent a plastic ball, and very flimsy small sponge by L&S Engineers. George didn't have them.

But not sure these are right? From memory, there was a far more solid black plastic plug with two 'fins' originally. Difficult to tell exactly as the one I have is in a very poor state (and no ball).

The ball and sponge sounds…

The ball and sponge sounds correct. Did LS put part numbers on their paperwork? I think that they are 25946 and 25947.

Yes they are listed as 25946…

Yes they are listed as 25946 (ball) and 25947 (pad).

Looks as though you have the…

Looks as though you have the correct parts.

I have a similar issue with…

I have a similar issue with a Villiers light weight 50cc.

I have oil on top of the piston. The oil fouls the plug, over time.

Other than that the engine starts and runs well.

I have been told it might have a broken oil scrapper ring. As the compression is good.

Did you solve your issue?

Broken scraper ring; very…

Broken scraper ring; very unlikely, but worn, almost certainly.

If the breather is in good order the oiling up is probably due to years of wear and tear. You either live with it or strip the engine , measure everything and compare with Villiers’ dimensions listed in the manual. Then when you know the worst, you are probably no further forward as you will probably find that oversize / underside parts are unavailable.

@wristpin, Just got around…

@wristpin, Just got around to fitting parts. Maybe I'm being dumb (likely!), but I can't see how this breather is meant to go together.

The old 'plug' is the black plastic item, in poor condition with two fins which correspond with the housing. And I have a flimsy sponge and a plastic ball. How does this all fit together? Tellingly there is what looks like a dent/wear from a ball in the cover plate....

Your black plug doesn’t…

Your black plug doesn’t feature on either of the two lightweight 150s that I have and doesn’t appear in the parts books that I have, so I’m guessing that it’s a lump of mastic, or some such, that’s been stuck in by a previous visitor! Hopefully with the correct breather doing it’s job, it will reduce the oiling issue; however, with an engine from the 50s or 60s such problems are inevitable.

This may reassure you that…

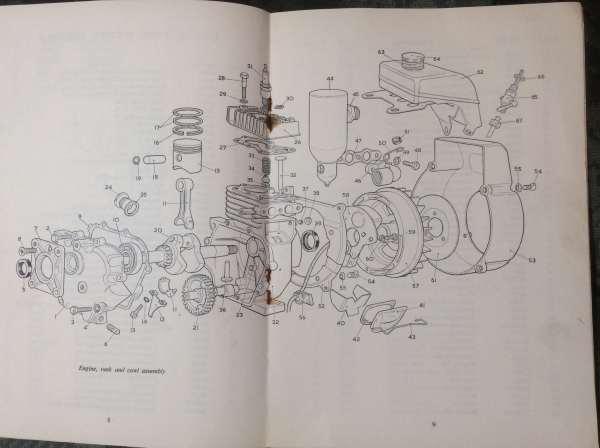

This may reassure you that the black plug doesn’t belong! Also, check that the baffle (40) is in place. It was missing from one of mine.

This may reassure you that the black plug doesn’t belong! Also, check that the baffle (40) is in place. It was missing from one of mine.

The plastic ball supplied by…

The plastic ball supplied by L&S is 8mm, and the hole is over 10mm, so it just falls straight into the valve chest, even with the baffle in place.

But my baffle is different to the one in the photo. It has notches that go round the pushrods, and has a slight cutout that aligns with the breather hole. So I'm wondering if this is a slightly different variation of this motor?

The cutout in the top corner…

The cutout in the top corner of the baffle is also clearly visible from my previous photo of the side of the motor.

From memory 8mm does seem…

From memory 8mm does seem rather small, but is about three years since I was into a Lightweight. Unfortunately I don’t have a spare cylinder block to look at; both my engines are built up on machines. One thing for certain is that the ball should not be able to fall into the valve chest. With the cylinder block laid on its side ( mag side upwards) the ball should sit in a seat machined into the block. The ball should be lightly held in place by the sponge and the magneto back plate. In operation the air displaced by the downward stroke of the piston, should lift the ball and vent through the sponge. On the upward stroke of the piston the ball should be drawn onto its seat , resulting in negative pressure within the crankcase, assisting the oil seals and gaskets to keep the engine oil tight. It should not need the baffle to keep the ball in place.

Ball size aside, from your image there’s little sign of a seat for it to sit in. What’s needed is another block to look at. Unfortunately the Maintenance Manual for the Lightweight Range of Engines, makes no reference to the crankcase breather whatsoever!

I’ve just browsed the L&S…

I’ve just browsed the L&S site and they list two breather balls. One is listed as EM2161 5/16” which is presumably the one that you have. The other 26553* for 125 and 150cc which could be the one that you need but they don’t specify the diameter, so it may be asking the question. If it turns out to be a larger diameter it could be the answer to you issue but it doesn’t resolve the question of the seat. May be worth a try.

* however my parts list gives 25946.

Your issue is more likely to

Your issue is more likely to be the result of worn valve stems and guides rather than valve sealing. Valve clearance ( assuming that they are too tight) is achieved by the removal of metal from the end of the stem, either by grinding or careful filing. It may be worth checking the condition of the crankcase breather, a ball and sponge installed between the valve chest and the magneto backplate. Correct operation of the breather maintains a negative pressure in crankcase which helps in keeping the engine oil tight. Tappet clearances are shown as 2-6 thou” for both valves.

The recommended engine oil of the day was Castrol XL SAE 20W-50 and the air cleaner maintenance was, wash, dry, immerse in engine oil and allow to drain before refitting .