Ransomes Clutch

I have a problem with Ransomes clutch on a Mastiff. All good, springs OK and strong. Shoes fitted correctly. Just engages at very low revs. Won't disengage until engine stalling. No high spots, drum and shoes clean and smooth. Linings approx 5mm thick. Any ideas other than try to find stronger springs please.

Forums

Ransomes Clutch

Ouch! That sounds expensive, is the bush made of some kind of exotic metal?

Mastiff clutch

Unobtanium mined near Ipswich !

Thank you although I had

Thank you although I had considered that and ruled it out as only a small fraction of movement. I just can't believe that this tiny movement can cause it to kick out and catch on the shoes and it certainly doesn't seem to be catching on the back plate.

Ransomes clutch

Unfortunately there's only one (expensive ) way to find out! I've encountered this problem several times over the years and it's always ended up with a new bush. Along the way I've seen various things tried, shims under the engine and spacing washers in the flex drive discs etc. I've even heard talk of cobbling up a drum brake to stop the drag.

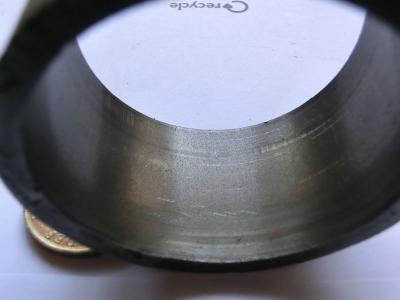

As I said in my first post there is very little sign of wear in a "failed" bush, usually just two polished lands where it had run on the machined spigot on the clutch back plate. I've had a scrabble around in the "bits box" and found a bush that was removed from a Mastiff for this very reason and you may just be able to make out the wear lines in the image. I don't think that the wear causes the drum to catch the shoes but allows the drum to sit on the spigot at a very slight angle and bind on it .

I've been discussing the issue with another forum member and he has come up with a couple of firms who offer various bush making materials but I fear that unless you can find an engineering works already using a suitable substitute you will be up against the "minimum order" issue so it may be a case of biting the bullet..

Don't take any notice of the cut in the bush - It's not original and I probably made it to ease getting it out.

An avenue that may be worth exploring is to find someone else who has worked with Ransomes Mastiffs of that era (later ones were/are fully hydrostatic) and see what is their take on the issue based on their field experience.

Sorry that this is out of sequence with the question but I haven't mastered the quirk of this forum that posts the answer before the question! Message to admin, How does one put posts in sequence? - latest last.

That darn clutch on the

That darn clutch on the mastiff was a pain in the you know what, as Wristpin says, you could never really see any wear in the bush, but you had to get the engine to tickover very slowly before the clutch disengaged. I have seen gearbox damage caused by users just slamming the gears in and out, just because the clutch would not disengage fully. The only cure is to replace the bush, having said that, over £100 for a bush is ridiculous. Have you tried obtaining a bush from a good bearing supplier, you might have to get one that is too long, but that is what hacksaws are for ;-)

That ******* bush!

Prompted by Hortimech and Hillsider I've had a look at Simply Bearings's website. They have an "oil filled bronze bush" with an id of 2,1/4", od of 2,5/8" and a length of 2,1/2" which other than being too long appears to be of the correct dimensions. I say "appears" because the one I have has been used as a press tool etc and could be slightly distorted. Including vat the bronze one it's a whisker over £30 with free postage.

BUT the Ransomes bush is not bronze but appears to be some sort of "gunmetal" material and seems to be harder than bronze, so there's an element of risk that it could prove to be unsuited to the application.

On the basis that other than time there is nothing to loose and assuming that you are not doing the job for a customer who may expect a perfect outcome you could just try pushing out the existing bush and heating it up in oil to see if it will absorb some and regain its "slipperiness".

While agreeing that over £100 for the bush is a bit much to stomach it should be remembered that back in 1990 the Mastiff was a £6000 machine and the last price list that I have, 2012, shows £10838.40 !!

It doesn't really matter what

It doesn't really matter what the entire machine cost, over £100 for a bush is extortionate, you could buy a pair of cylinder bearings for less than that and there is a lot more work in making a bearing compared to a bush.

Oh and £10,000 for a commercial mower is cheap nowadays ;-)

Mastiff Clutch

Thank you both for the information. That gives me a couple of options to try. It is for me not a customer but I intend to sell the machine so would require it to be working properly for that purpose.

Ransomes Clutch

From wristpins description and photo of the original bush I suspect that the material used by Ransomes may have been Leaded Bronze it fits the description being both harder and stronger than the oil filled sintered bronze bushes and is available in bar or tube form for machining to size. A Google search will reveal several suppliers and a description of it's properties

The downside is that it is quite expensive unless you happen to find a machinist that has some in stock.

Just a thought here that you might be prepared to try on the basis of you cant make it any worse!

Remove the bush from its housing set it up in a lathe and knurl the outside diameter of the bush, this should increase the interference fit when you go to re fit the bush. This will then hopefully shrink the internal diameter enough to eliminate the wear.

if any one has already tried this knows that it is a waste time don't be afraid to speak up you could save Steve some time!

Ransomes Clutch

Thanks again for the advice. I tried the following and don't know whether it was ever viable: As the bush only bears on two shoulders on the shaft, I split the bush in two, therefore making two, smaller bushes, reversed the two halves and pressed them back in again so that the unworn, inner part of the bush is now in contact with the shoulders of the shaft. Sadly the play was still there and it didn't work. Makes me think the shaft is worn.

Ransomes Clutch

Oops!!!

It seems as though you are running out of options here and have reached the point where decisions need to be made re how to move forward and cure the problem.

Ray.

I wouldn't think so, never

I wouldn't think so, never seen one that was worn, though there is always a first time, replacing the bush always cured the problem for me. As I said that clutch can be a real pain, you cannot see wear in anything, but replace the bush and it works. Other things that I can think of, is the engine ticking over slow enough? What engine is fitted, is everything in line?

Ransomes clutch

Thank you and I will try a bush.

Ransomes Clutch

Latest development. I purchased the bush from Simply Bearings 2 1/4" ID and 2 5/8" OD. Cut it down to size and it fitted fine after putting bush in freezer for 1/2 hour. Slightly less play but still same problem. This was a sintered bronze "oil filled" bush and even with the slight amount of play I just can't understand how it can bind as it does.

Bush

Frustrating but. It was a punt using non genuine and a material different from the original. Unfortunately there is only one (expensive)way to find out if that is the case.

I can only say that I have never experienced a failure using the genuine Ransomes bush.

Ransomes Clutch

Thank you and I guess that has to be the next move

Ransomes Clutch

Finally bit the bullet - ordered the original bush. £106 plus VAT. Fitted it easily - and it made no difference whatsoever. Does anyone know if stronger springs are available?

Clutch bush

Oh dear, well I suppose that there has to be a first time.

Not aware of stronger springs but unless the tick over is too high I doubt if it is the shoes engaging.. What engine is on yours?

May be worth a call to Ransomes technical. 01473 270000.

Ransomes Clutch

Thinking outside of the box here but how difficult would it be to remove the clutch shoes and run the engine without them in place? This would help to narrow down possible causes of the clutch drag.

Another way to check what is going on could be to smear the friction area of the clutch drum with something like engineers blue or even a very thin smear of grease that would transfer to the shoes if they are engaging at idle - this is assuming that you are able to start the engine at slow idle.

Re the springs it is possible that they have lost tension through stretching over the years of working in the clutch, I guess the only way to check this would be to compare them alongside a new spring.

Ransomes Clutch

Thank you for the advice. It's easy to run it without the shoes so I will try that. Springs are very strong and not stretched but obviously not strong enough. Might try that technical help line.

Ransomes Clutch

OK. Tried without the shoes. Still binding, so it isn't the shoes. Must be the bush/shaft.

That ***** clutch!

This is grasping at straws, but just wondering if the two flex disks in the drive line have taken on a bit of a "set" and are putting a strain on the the relationship between the drum and back plate. Not got a decent illustration to look at but is it possible to un bolt one or both and move them through 90/120 degrees in relation to the tube that separates them. No real logic to this but may be worth a punt.

Other possibility, what is the surface condition of the back plate spigot that the bush runs on? You could try polishing it up with something like Solvol Autosol or Brasso on the back of a strip of emery tape.

Ransomes Clutch

This problem is getting more interesting at every turn! Probably doesn't feel that way to you though.

As wristpin has said the condition of the flexi couplings is a very good point to check out, as well as taking a set over the years they may have age hardened thereby limiting the amount of flex when running, also check that the shaft has a small amount of end float at the point where the bearing is located if there is none it could be a cause of the shaft dragging.

It may be an idea to slacken the coupling bolts enough to introduce some movement into the couplings just to try and prove something while you still have the clutch shoes removed.

Ransomes Clutch

Ran it without coupling and drive is solid at anything over stall revs.

Ransomes Clutch

Free play on ends so not binding on backplate or circlip

Ransomes Clutch

Hmm, not going to give up is it.

Not wanting to go over old ground here but something is being missed that is possibly staring us in the face. I can think of some questions the answers to which may throw up a clue to what is happening.

Do you know the design idle speed for the engine and is your engine set to this speed or lower?

Does anyone know the design speed that the clutch should engage the drive at? Any engagement below this speed would make me think that the springs have gone weak irrespective of how they look.

Have you double checked the engine /shaft alignment to eliminate any drag in the bearing also is the engine mounted securely? This may sound an odd thing to ask but a cracked or loose mounting may not be obvious but could allow movement when the engine is running.

Ray.

Ransomes Clutch

Just for clarification - that was no shoes and no coupling. must be binding on shaft.

Ransomes Clutch

If you use a length of wood as a brake on the outer surface of the drum can you stop it turning?

Not without extreme pressure

Not without extreme pressure and only at very low revs. Above idling it's a solid drive. it can only be binding on the shaft, which must be due to wear on the shaft as the bush is new.

Mastiff clutch

If the clutch is "engaged" with no coupling or shoes it must be dragging on the spigot but going back to basics please answer the following -

With the engine not running does the clutch drum spin freely on the back plate?

Do you know the date of manufacture of the Mastiff ?

What engine is fitted?

Is it the original engine?

What is the lowest idle speed that you can achieve and still give a clean pick up when the throttle is opened?

Edit

Just read your reply to Ray re stopping it with bit of wood. Have you tried my suggestion for polishing the bearing surface of the spigot?

Yes it spins very freely.

Yes it spins very freely. Shaft is very well lubricated and smooth, haven't tried polishing.

Don't know the age sorry but it's old. Engine is a Kubota 7.2HP and prob not original but is well mounted and secure.

Not sure of engine speed but it only frees up at sub-stall speeds. It will idle at very low speed but not slow enough to free up.

Mastiff clutch

Are we right in thinking that you have acquired this machine and don't know much about its history? If it is "old" it would possibly have originally had a JAP or MAG engine. I do not have any reference material relating to later Mastiffs but I do know that they were fitted with with Kubota engines but I thought that it coincided with the adoption of hydrostatic transmission so perhaps it is a conversion. Perhaps someone with more current Ransomes knowledge can clarify this.

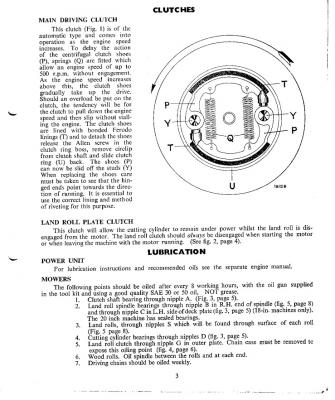

In your original post you say that the shoes are correctly fitted - that would be with the pivoted end leading. I say this because a while back there was some quite heated discussion on another forum with a number of people telling me that I was wrong in saying that, and giving all sorts of "scientific explanations" as to why I was wrong. After it had rumbled on for a while I posted Ransomes' instructions on the matter - end of!

The illustration below refers to a Marquis but the same applies to the Mastiff.

Yep - all agreed but here we

Yep - all agreed but here we are talking about the drum jamming on the shaft now - which is a different matter as we've taken the shoes and the link out of the equation. So I guess it's back to the drawing board. Is there an answer other than renew the shaft?

Ransomes clutch

It's all very strange and I think that without actually seeing it we have exhausted "on line suggestions" not that its much help to you.

I've lost track of what you have tried and in what order but would suggest reassembling the the couplings and drum minus the shoes to eliminate any "droop" as suggested by Ray. If it's still driving, see if you can use the bit of wood to gently lift the drum to see if that takes any binding force off the bush and spigot . You could also loosen the engine mounting bolts and see if any available rotational movement makes any difference.

Have you spoken to Ransomes' technical dept? There may be someone there who already knows the answer!

Ransomes Clutch

I don't wish to confuse things here but is it just possible that the drum is jamming on the shaft because there is no support from the drive shaft allowing it to run out of true.I appreciate that this does not cure the original problem but it may be clouding the issue.

I have to say that apart from going back to the beginning and checking all settings and components etc against known Ransomes information I am completely out of ideas.

Ray.

Ransomes Clutch

Bring it to the AGM?

Is there any chance of a few

Is there any chance of a few pictures, When Ransome's fitted the MAG/Kubota (not to be confused with a cast iron MAG engine) engine originally it used the camshaft for the output drive and the engine ran in reverse, this allowed the clutch to turn slower (half engine speed) at tickover. Now if some has replaced the engine with the wrong one, then this may be the problem.

Thank you for all the help

Thank you for all the help and suggestions. I tried the Ransomes technical line and they have asked for an email, which I duly sent and am waiting for a response. I will try the support thing from the coupling but I suspect that it will not make and difference, however i will post a result in due course.

Mastiff clutch

Been there! Been driven nuts by that problem!

i think that you will find that the problem is caused by wear in the big bush in the centre of the clutch drum and supports it on the back plate that carries the shoes. The wear allows the drum to drop a fraction and it picks up on the back plate causing your problem.

The wear is often not visible to the eye but changing the bush cures the problem.

The part number is/was GSF3010ZH and the last price I had for it was £106 plus vat !