Qualcast Classic 35S running problem

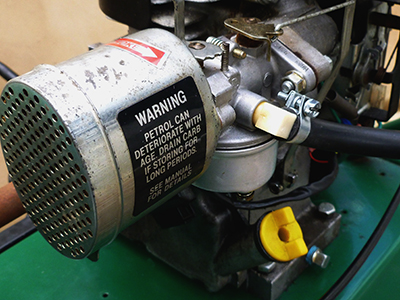

I recently bought a 2000 Qualcast Classic 35S which is in quite good condition. The motor starts readily enough but dies soon after running the blades and/or roller. At first I assumed that it was a fuel supply problem but having thoroughly cleaned the carb, changed the fuel, removed the air filter and checked the hole in the petrol cap wasn’t blocked, I now think the problem maybe electrical. (I even changed the carburettor with one that is definitely okay, but to no avail).

I renewed the spark plug but the problem remains. Could the magneto be at fault and if so, where can I get a replacement?

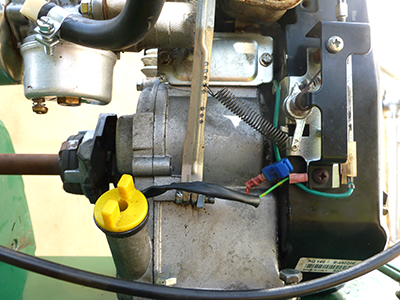

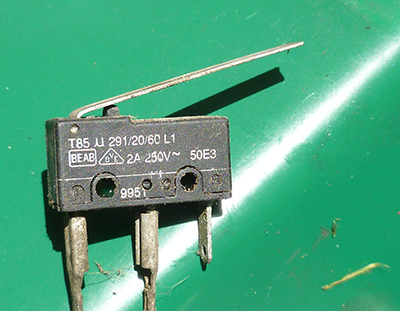

On removing the magneto, I found an Otehall microswitch located under the drive housing. It is connected to the green wire coming from the magneto and earth. The microswitch housing has lost half of its shell (and some contents?). Can anyone please tell me what the switch does and if I can replace the housing and possible contents?

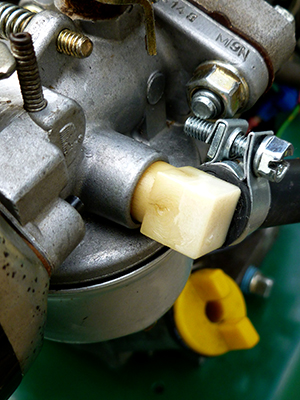

I attach some photos for clarity.

Many thanks in advance.

Dave

Forums

Think that it had a large

Think that it had a large ball bearing in it. I was told that it was a standard fitment for German market machines and that some found their way into the home market inventory. The advice at the time was to remove it and insulate the wire from the mag so that it could not earth.

Am I correct in thinking that

Am I correct in thinking that some machines used a Mercury switch and that it was sometimes mounted on the plate where the throttle cable attaches?

Last time that I saw a

Last time that I saw a Mercury switch was on a car boot lid in the 60s. Never seen the arrangement that you describe but that's not to say...........

Maybe I am dreaming re the

Maybe I am dreaming re the use of Mercury on a mower we can always blame it on my age!

Going off topic here is something to get the grey cells going - Does anyone know where Mercury is used as a bearing?

May be your avatar?

May be your avatar?

Spot on, but knowing my back

Spot on, but knowing my back ground did give you a head start.

Here is an explanation of how it is used but I had to go over the pond to find the best description of its use, hope you find it interesting.

Actually no! Memories of a

Actually not the association with your good self but memories of a visit to Dungeness light house as a child . I think that I can remember that the weights for the clockwork mechanism hung down through the floor of the lamp room into the room below.

That's ok and you are quite

That's ok and you are quite correct about the weights driving the mechanism but I think we should now allow the thread to return to its original subject- the Qualcast 35S and it's running problems.

Many thanks for your

Many thanks for your responses. From its shape, I think that the switch housing could well have contained a ball bearing and I rather like the design and idea.

I have taken your advice and removed the switch and insulated the wires. The engine fired up and ran very well for a few minutes, even when driving the roller. Unfortunately it than died as before and although would readily restart after a few seconds, died again after a few seconds. Could it be that my magneto needs replacing?

Dave

From the way that he engine

From the way that he engine fires up quickly after stopping it does sound like a fuel supply problem.

Have you checked out the delivery of fuel at the end of the fuel hose? I am fairly certain that some of these machines have a small filter contained within the bore of the hose that due to its small size is easily blocked. If so equiped replace the filter with an inline filter.

Ill go along with a possible

I'll go along with a possible fuel flow problem. Turn the fuel off, pull the fuel pipe off at the carburettor end and hold it over a suitable container, turn on the tap and watch the flow for half a minute; it should remain at full bore and not falter. If it starts to slow down undo the tank cap a turn. If it then speeds up, suspect an obstructed breather hole in the cap.

That's the cheap fix but there is the possibility of the electronic ignition unit breaking down. The electronic combined coil and trigger units fitted to those machines were prone to a separation of the plastic shell of the coil and the potted windings and the electronic "gubbins" . In my experience nearly every unit that gave trouble exhibited that separation. They could sometimes be revived for a while by a spell on top of a warm radiator or in the airing cupboard (with the welding rods!) but it was not a lasting solution even with a sealing compound applied to the separation. The only permanent solution was a new unit, and if memory serves correctly, at around £50.

If shopping for new old stock or a used unit, be aware that early units were of the capacitive type and later ones inductive and that they are not interchangeable without changing the flywheel as well. A quick check of the type of unit that you have is that the coil armature of the capacitive type has 2 "legs" and the inductive 3.

Many thanks to you both. I

Many thanks to you both. I agree that the problem is still possibly fuel supply related but appreciate the magneto information. I will continue testing and report back.

Dave

I think that the plastic

I think that the plastic petrol intake to the carburettor may be leaking. Can anyone tell me how to extract it please?

Many thanks.

Dave

Think that it's just a press

Think that it's just a press fit, may be with a bit of sealant applied before being pressed into place. If you need to remove it , grip it with pliers and put a spanner on the square body and gently rotate it a few degrees back and forth while pulling outward. Unless you can actually see the fuel dripping out I wouldn't worry about the staining on the fitting. Even quite a severe leak is unlikely to be the cause of your stopping issue.

Thanks Wristpin. There is a

Thanks Wristpin. There is a leak at the plastic nozzle (now made a bit worse having removed and replaced it without a sealant!) and I agree, it is not the cause of the engine stopping. However it must be an indication of the problem. The engine starts and runs well for about a minute. At this point (or if the roller/blades are engaged) the engine dies and then a leak appears at the nozzle. Obviously something is obstructing the flow in the carburetor, causing the fuel to back up but I can't find what is causing it. The engine restarts after a few seconds but runs for increasingly shorter periods. Does anyone have any ideas?

Many thanks.

Okay. I have now acquired a

Okay. I have now acquired a second Qualcast Classic 35S which is running well. I have transferred the complete carb and fuel tank to the problem mower and it is still dying after a minute or two. So the problem cannot be the fuel system. I have also changed over the magnetos, again to no avail. Can anybody advise me what to try next please?

Unusual, but worth checking

Unusual, but worth checking the valve clearances. If they are tight , when the engine warms up they may close up altogether resulting in the valves not sealing properly.

This is new territory for me.

This is new territory for me. Can you please talk me through it?

Have a look at this

Have a look at this

https://www.youtube.com/watch?v=yQiE50YAPuA

BUT I WOULD SUGGEST THAT you should take the readings with the piston 1/4 passed (down from) Top Dead Centre so as to avoid any possibility of an automatic compression release mechanism causing a false reading leading to an excessive gap being created.

Obviously you need to Identify your engine and look up the clearances specific to it but the clearances for the Tecumseh engine in the video wont be far adrift from yours .

I would suggest that if you have at least five thou on each valve your problem lies elsewhere.

Many, many thanks. I think

Many, many thanks. I think you've hit the nail on the head. The inlet valve had only 4 thou clearance and the exhaust had no clearance at all. Whilst I have the cylinder head off, I need to change the head gasket. Does anyone know the correct torque setting to tighten the cylinder head nuts?

Okay I have now reground the

Okay I have now reground the valves and got them to the correct gaps (6 thou inlet and 11 thou exhaust). I have replaced the head gasket. The engine starts and runs very well for four or five minutes and then dies. It will not restart until it has cooled completely. I assume that something is happening when it gets hot. Does anyone have any ideas please?

Two things to check now:-

Two things to check now:-

First is the fuel filler cap vent, this can be proved by slackening the cap to allow free flow of air.

Second is spark, check that a spark is still visible immediately after the engine has stopped and before it cools.

Both the above are valid

Both the above are valid possibilities, one cheap and the other expensive but hopefully already explored following my post of the fourteenth of April. Not sure where that leaves us; unless, of course, you didn't check them out then!

I did think that I might be

I did think that I might be stating the obvious but then it sometimes pays to revisit basic checks now and then, as it sometimes catches out the intermittent problems.

Thank you both for your

Thank you both for your responses. I was made aware of the possibility of a vacuum in the petrol tank and there is a suitable hole in the cap.

I tested the engine today and, of course, it ran perfectly for fifteen minutes without stopping.

Should the engine fail again and have no spark at the plug, what would be you diagnosis?

Possibly the electronic

Any correlation between the appearance of the fault and the ambient temperature? Decidedly cool here today.

Possibly the electronic ignition module breaking down - go back to my earlier post about the two different types and the physical signs of deterioration of he coil's insulation. Also check that you have not got an incorrect pairing of spark plug and plug cap. ie a suppressed cap and a resistor plug.

These links may be interest

https://www.dropbox.com/s/ajrvuul2oiq66qu/Suffolk%20and%20Wipac%20servi…

https://www.dropbox.com/s/8ex4w9wkhhnd7ur/SIF%20electronic%20magnetos00…

I have now checked the spark

I have now checked the spark immediately after the engine fails and it is fine. I have also used a compression tester before the failure and immediately after and the readings were the same. I have exchanged the carburetor and fuel tank assembly and the problem still persists. The engine need to cool completely before it will restart and run again, trying to start it after just five or ten minutes is a no go. After the valves had been correctly adjusted the engine has run better than ever before. However the problem persists. It appears that something is happening when the engine has reached running temperature. Any ideas?

OK, have a plug spanner handy

OK, have a plug spanner handy and when it stops, put it on choke and pull it over a couple of times . Whip the plug out ( gloves, hot) and see if it's wet or dry. If wet, for some reason yet to be found your " good spark" is failing to ignite the mixture. If dry, we are back to a fuel supply issue , possibly a vapour lock.

Have you considered trying

Have you considered trying another spark plug? It does not happen often but even new plugs have been known to go bad occasionally.

I am fairly certain that the

I am fairly certain that the switch located on the drive housing is a tilt switch that is designed to kill the engine should the mower tip backwards. I cannot comment on the missing parts but suspect it was some kind of weight that rolled over the arm of the micro switch to operate it.

My inclination would be to disconnect it (temporarily at least) and run without it in circuit to eliminate it as a possible cuase of the engine cutting out while under way.

good luck