Suffolk Colt Ignition System

Hi I hope that someone may be able to help me.

I have a Suffolk Colt mower that has an oil soaked wire air filter and the number 374 7 7 stamped on the R/H Side plate.

I decoked the engine several years ago, but have been unable to get it to run because of a lack of spark.

Over the last couple of years the coil, condenser, points, HT Lead, spark plug and suppressor have all been replaced. Also the flywheel has been re-magnetised.

I have checked it out with test leads and a 1.5v battery and it produces a reasonable spark. But with the flywheel back on there is no spark when the engine is turned over.

Unfortunately I disposed of the old points by mistake, but I seem to recall that they had a slightly longer heal on them. If this was the case would it affect the ignition because of the point where the magnets pass the coil.

I would be grateful of any help that anyone could give me, before I finally pull the last of my hair out.

Forums

An image of the inside of

An image of the inside of your magneto will be useful to identify the " generation" of points. The early ones had what I call " seesaw" rocking points and the later ones the more familiar compact right angle ones. If you have the former there were two distinct. patterns with different configurations of heal angle - one more often found on Villiers engines.

Your set up should really be tested with a proper ignition testing rig - not sure about the validity of your battery method. Another option open to you is to fit a solid state trigger module in place of the points and condenser .

Thanks for the replies.

Thanks for the replies.

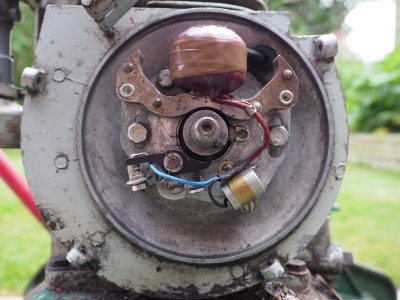

Here is an image of the magneto.

All of the parts replaced have been new.

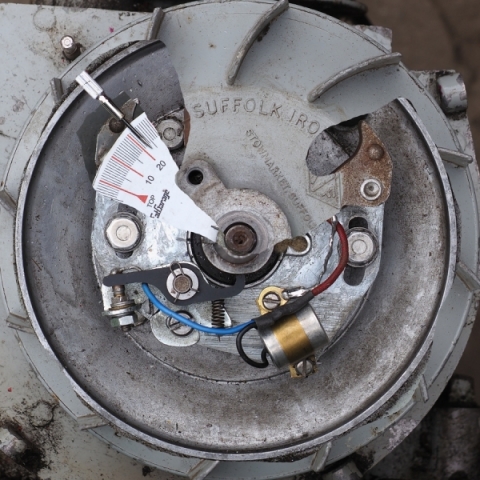

The points gap has been set to 20 thou.

Wristpin, you say that there were two distinct patterns of early points. I think this may be the problem. Do you know where I could obtain them from?

That is the early mag with

That is the early mag with the "seesaw" points. Ignore my comment about the two patterns - think that I was having a bit of a senior moment there, it is the Villiers version that has two different cam heal profiles.

A couple of thoughts . Are the points actually fully opening and closing electrically as opposed to visually. I have had the situation where it has been necessary to un-bolt the fixed contact point and space it with a small washer to achieve both a firm closure and the correct gap using the slotted adjustment range provided. The blue wire in your image obscures things a bit but is the "return spring" in place?

I've only once had a flywheel re-magnetised and that was to try to achieve better lighting on a 1950s Lambretta - no improvement! I'm not conversant with the re-magnetising process but assume that the people with the re-magnetising equipment are competent to carry it out , but is there any possibility that the flywheel could have been incorrectly polarised?

One more thought! I see that you have the stator plate mid way in its adjustment slots which should be OK but have you actually set the timing to specification which is , 22 - 24 degrees Before Top Dead Centre.?

I wondered about the points,

I wondered about the points, I thought I was having a 'senior moment' because I could only remember one set of points ![]()

If everything is new, then either something is faulty (has been known) or there is something wrong with the points. Is there connectivity between the fixed point and the stator plate ? are the points clean, is there a good joint where the wire is soldered to the moving point, are the points set correctly (20thou or .5mm) or to put it another way, peer very closely at the points. If you are 100% sure there is nothing wrong with the points, then you need to get the coil and condenser tested with a specialised machine, there is no other way to be sure they work.

Moving the stator plate about will not make the spark appear, it will just alter when the spark happens.

I have been thinking back and

I have been thinking back and my Father must have purchased the mower back in 1967 or 68 second hand.

Correct me if I am wrong, the points stay open for most of the rotation of the engine, when they close the condenser charges and then discharges when they open again, causing the spark.

I have had a timing disk on the end of the crank shaft and a combi check across the points, this lights up and makes a noise when there is continuity.

The points are closing at 50 Degrees BTDC and opening at 23 Degrees BTDC. Surely this is far too soon before TDC. I am not able to adjust the back plate around by very much.

As I have said I do not have the original points, but I thought that they had a longer heal and have been trying to work out if this was the case what affect it would have on the timing or the relationship of the flywheel magnets to the coil.

The cam will only fit onto the crankshaft one way?

The flywheel was re-magnetised by Vintage Magneto’s who thought that it would make little difference, I was clutching at straws! They also checked the stator plate at the same time and it all tested out fine. It just does not work when all put together on the mower!

See my last post , the timing

See my last post , the timing is specified at 22 to 24 degrees BTDC , so your 23 is spot on.

Coincidentally I've just been tracking down an ignition issue on a Villiers F12 Sloper which, once running, ran well but was a pig to start. To cut a somewhat frustrating tale short ,fitting a new coil in place of one that had checked out as fine on a dedicated coil tester , cured the problem.

Despite the pedigree of the remagnetisers , the possibility of reversed polarity cannot be ruled out. The way to check is relatively simple, remove the flywheel and with the magnets positioned at roughly twelve o'clock , offer a small compass ( of the map reading variety) to each in turn and note the polarity indicated by the needle. I will do the same to a stock engine and we can compare results.

OK, you are wrong

OK, you are wrong ![]()

The points are closed most of the time, when the heel of the points hits the bump in the cam, the point are opened, and the spark occurs (or should do). This makes me wonder if you are setting the points in the correct place, with the heel of the points on the top of the bump on the cam.

Hortimech said “The points

Hortimech said “The points are closed most of the time, when the heel of the points hits the bump in the cam, the point are opened” I agree with you for most engines, but for some reason the cam sleeve is round with an indentation. I hope that you can see this on the image.

Wristpin I have only recently replaced the coil although the previous one had checked out O.K.

The following image shows the South Pole of a compass pointing to the North Pole of the Flywheel.

The following image shows the North Pole of a compass pointing to the South Pole of the Flywheel.

I have made up two composite images of the ignition system at 23° BTDC and at TDC I hope that they may be of some use.

I have now managed to get a weak spark by moving the stator plate clockwise more towards TDC and closing the points to 18 thou, but it will not jump across a spark plug

Hortimech's comments are fine

Hortimech's comments are fine for conventional points where the lump in the cam opens them but for the "seesaw" ones used in this case the process is reversed - the points are open for much of the rotation and do a quick shut and open over approximately 30 degrees of rotation when the heal drops into the small area of reduced cam diameter.

This image shows the Suffolk "seesaw"cam with one from an Aspera and a Villiers Sloper.

Or, perhaps not, there seems to be a glitch in the image posting software .

<img src="/sites/default/files/styles/large/public/memberuploads/user1261/CIMG4448%20%28Medium%29_2.JPG?itok=kEr9EQ7o" width="480" height="360" alt="" class="image-large" />

Don't think that there's any point in continuing as I need images to illustrate further points.

OK, I got it wrong, but in my

OK, I got it wrong, but in my defence, it has been over twenty years since I last saw one of these stator plates. Looking at the close up of the points, the two points don't seem to be parallel. It also shouldn't make any difference to the actual spark where the stator is positioned, it will just change when the spark happens. Has continuity been tested between the fixed point and the stator plate ? what about the earthing wire for the coil, is this actually connected to the stator plate firmly.

It is hard to say what is wrong with something from a distance, mind you, it is sometimes hard when you are stood next to the engine. This could be something as simple as the engine not being spun over fast enough when testing the spark.

No need for " defence" , I

No need for " defence" , I was fortunate enough to have an engine in the " may come in useful dept" and spent an hour or so playing with bits of tape and a timing disc: aided by a Dy- tone, a cunning bit of kit made and sold by Rupert Ledger Ltd back in the 70s. With no dismantling needed, connect one lead to the HT lead and the other to an Earth , Switch on and it emits a tone which changes as / if the points open and shut. With clean points shutting squarely there is an abrupt change of tone but if dirty or not making a good contact the change is blurred. A great time saver in the days when everything had points, both for diagnosing points issues and for setting basic timing etc.

Still not able to post images

Still not able to post images but a couple of observations.

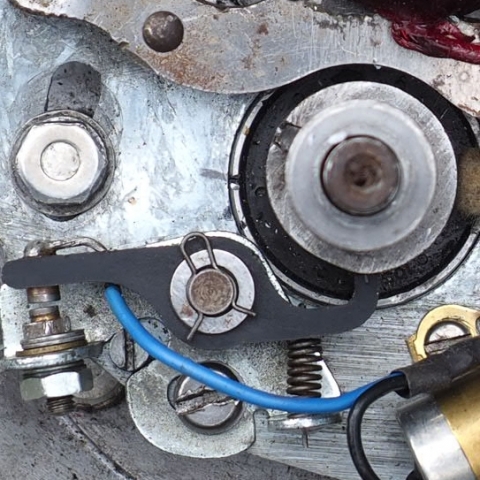

Your close up image of the points shows two washers packed under the fixed point raising it far more that I've seen on any of the examples in my possession.

The second observation is that none of my examples have the stator positioned as in your pic - they are almost diametrically opposite.

Now, when the points are closed - i.e. the rocker heal on the low point of the cam, is there a slight clearance between the heal and the cam - confirming that the points are fully closed. On my "experimental" engine that is producing a good spark I can slip a 2 thou feeler between the heal and the cam when the points are firmly shut. If when the points appear to be shut the heal is still in contact with the cam there may be a contact problem.

It's my suspicion that the additional packing washer under your fixed point may have a bearing on your problem.

Finally, you say that you have a new condenser, has it actually been tested? My tester shows the condenser being charged and that sequence stops when it's full charged. If it continues to charge it is leaking. When charged, one observes it for ten seconds to check that it doesn't discharge on its own - a "bad" condenser will do that .

On the question of polarity, I seem to be achieving the same readings, i.e. with a clockwise rotation of the flywheel the south pole is passing the coil first.

Hopefully Forum Admin will soon sort the image posting issue.

Right, I'm told that we are

Right, I'm told that we are back in business

Top two are conventional cams with a lump to open the points and the bottom one is for the Suffolk rocking points where the dip closes then opens them.

Two thou feeler between the rocker heal and the cam with the points firmly closed - one thou would be fine, just needs to be some clearance to ensure that the points are properly closed. . Also note the position of the stator holding bolt on this mag giving a good spark.

Assuming that the coil and condenser are OK the above setting should produce the desired result.

The points had extra washers

The points had extra washers because they would not close properly.

I have been playing around with an old set of points that I found in the garage. They are very pitted, but after cleaning and installing them I have managed to get the mower to run!

I cannot explain why but the points are closing 10° earlier. I had checked the gap between the cam and the heal before changing them, it was six thou, and after it was the same. Because the points are remaining closed for longer the magneto is obviously generating a higher voltage.

I will now get another new set of points and hopefully everything will be fine. Then to get the blades sharpened and a bit of paintwork.

Thank you very much for your help wristpin.

There were three types of

There were three types of ignition systems used on Colts. The earliest used a cast zinc? one piece flywheel and the HT lead is soldered to the coil. The second used a cast iron flywheel, HT lead screwed into coil with separate condenser, the third was virtually the same as the second, but the condenser is now embedded in the coil.

You say that you have replaced everything, but are the replacements new or second hand ?

If second hand, are you sure they are not faulty ?

If new and the coil is a black encapsulated one, have you replaced one without an embedded condenser with one that is and are still using a separate condenser ?

Are you sure the points are clean, they must be spotless, try putting a piece of thin clean card between the points, then close them by rotating the crank, now pull the card out, it should come out clean.

Finally, what have you set the points gap to ? It should be 20thou for the earliest type and 18thou for the other two.