Ransomes Marquis rear roller.

As there are several subscribers working on Marquises and asking similar questions this may be of use .

Roller lubrication - oil not grease. The oiling nipples are straight, no bulbous end like the modern "lock on" ones.

This one is from a cylinder bearing carrier, the ones in the rollers are of a similar shape but are unthreaded, press fit ones with no Hex.

Oil gun

Roller ratchet

The ratchet mechanism that's held to the shaft with a bolted cotter pin similar to a push bilke's pedal crank. It's the free moving pawls that clank when the machine is pushed forward.

Forums

My Sealey grease gun arrived

My Sealey grease gun arrived just now and I discovered it has two tips, one the conventional clip type and the other looks like it was meant for oil nipples as it has a concave fitting, so apart from the diameter of the nipple head I also need to know th head hight as the connector I have has a depth of 5mm which may need adjusting. I can just get the gun stem through the hole

Questions, Questions!

Questions, Questions! Ratchets / swinging pawls. They seem to look after themselves. The thing that they don’t need is anything that thickens up or attracts dust and stops them engaging.

How much lube through the nipples? Guess work! If each roller spins freely and smoothly, you’ve probably got the oil where it’s needed. The difficulty is knowing whether the oil is passing through the nipple to where it’s needed or is squirting out sideways and filling up the roller.

Oil, not grease. No myth, I assure you. If you’ve ever had to spend several hours sweating blood freeing off a seized roller assembly you would never doubt that oil is the way to go.

Combine harvesters. In the late 60s I drove an old Massey for the whole harvest which started about now and extended into October. I can’t remember how many grease points there were but greasing up took about an hour, needed the suppleness of a contortionist and left one feeling that one had already done a day’s work. There were five machines in the field and on a good day we did 100 tons. On the same farm today, two Claas Lexions do over 50 tons an hour each.

Nice initial post - thank you

Nice initial post - thank you, coincidentally OILED mine today :-)

Thanx WP we are on the same

Thanx WP we are on the same page

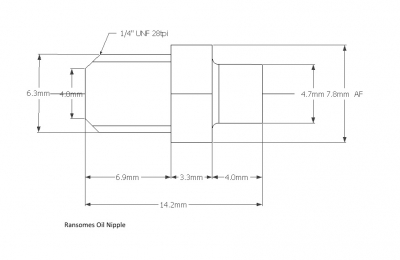

Have retrieved a mythical oil

Have retrieved a mythical oil nipple from an accessible point. I enclose an eng sketch of the little beastie. Its not available on ebay AFAIK but modern bulb nipples that fit a conventional grease gun can replaced. Its a 1/4 unf thread type and uses a 7mm socket. The old one needs a 5/16 AF socket. I found my 8mm copper tube fudge was quite a close fit and may or not have solved the roller problem

the roller problem

I am intrigued that the ratchet mechanism survives without attention seeing as its exposed to ground dust and clippings. I guess any oil or grease in there as you say would attract dirt and gum up the works. It also seems to me that it would be a disaster for the roller to become waterlogged. So a big warning then - KEEP YOUR MOWER DRY

Am I right in assuming there are two ratchet mechanisms one at each end of the half rollers

I have found one roller drum bearing lube point near the clutch side sticking up on a stub, but I am mystified where the lube point is for the other side bearing. Is it only accessible by taking off the side plate?

Press in nipples are

Press in nipples are available from Ransomes agents, albeit with the snap-on shape.

The nipple on the stub lubricates the roller shaft in its plain carrier bearing. The other end is lubricated by a nipple screwed into the end of the shaft behind a rubber plug in the RH side panel. Later 18s and 20s had sealed ball races. All the lubrication between the rollers and the shaft is via the nipples embedded in the rolls themselves.

Your machine has a centre mounted ratchet assembly the same as the one in my images. Six pawls, three for each roller.

Later versions of the Marquis, the 45,51 and 61, have outboard roller ratchet assemblies.

All good stuff coming through

All good stuff coming through. I am making a special coupler to put on my shiny grease gun to suit this press nipple. It has a 3/16 head and may benefit from a O ring seal in the couploer

Will post detail, suppose everyone will want one now. I have seen one of those early grease gun, painted a sort of blue/silver if I recall. Be better to get a std grease gun modded - grease gun thread is 1/8" bsp std fitting

OK yes I found it under a

OK yes I found it under a clump of greasy mud, no rubber cap. I really will have to force myself to take this roller apart but I want to cut some grass first

It seems to me that these mowers only survived cos

a) only used in the dry growing season,

b)only once a week, maybe 20-30hrs pa

c) kept in dry storage

d) probably only serviced once in 3 years as the blades went blunt

like many things it can be 100% reliable if you never switch it on

Still as I dig into my Marquesa I am pleased she hasnt been mauled by a bodger (a sure sign is burred nuts and bolts). All my visible nipples are suitably modernised and waiting for lubrication with EP90

Still bottom line is that these cylinder mowers do need some mechanic aptitude to keep them in order, not like a simple throwaway rotary - wash your mouth out

There is life under sludge

There is life under sludge

that grease gun may well have been an Enots part marketed by Tecalamite, garage outfitters, used in the BMC days for greasers and oilers

still cant find an example of the ransomes special nipple. what shall we do with our rollers - watch this space

OBTW I came across this

https://simplybearings.co.uk/shop/product_info.php?products_id=780006&v…

You should add to your list

You should add to your list of survival factors that despite your continual criticisms they are a simple well-built machine that probably started life in the hands of professionals who maintained them "by the book".

Why propose to use an EP oil when none of the bearings in question is going to exert much shearing force or require an extreme pressure lubricant, and the manufacturer specifies SAE 30 or 40. Ransomes knew best - usually.

No WP I disagree, its not

No WP I disagree, its not well built. there are numerous faults built in its design. From an engineers view it is agricultural a poor relation to model T fords

. I am an ex biker and formerly an engineering apprentice and I can spot all these discrepancies. Just cos its Ransomes doesnt make it next to god. You say you ran a lawnmower business, you must then know what a thankless task it was trying to offer customers a service agreement at a price they would want to pay. Could you have turned around a Marquise after 3 years inside 3 hours stripped sharpened and ready to go with 3 months guarantee for say £60 or whatever - tell us

OBTW ep 90 is thick oil and stays in place and doesent evaporate. Slow moving bearings, dont be a Luddite

Lets not be hypocritical

I am a retired engineering design manager and I dont put up with ill informed rubbish

actually I think they just

actually I think they just made jobs for the boys and agents, manual says lubricate after each day

I am a retired engineering

I am a retired engineering design manager and I dont put up with ill informed rubbish

So I'm sure that you appreciate there's a big difference between "playing" at home and the responsibilities of running a business with employees and customers and all that goes with them.,

Model T Fords were the bees

Model T Fords were the bees knees in their day and they still look ok.

In all my years designing, I

In all my years designing, I never deliberately created anything that had built in obsolescence or obtuse maintenance procedures (like British Leyland). It seems you dont like change for the better. Maybe I should keep quiet about my improvements to the infamous Ransomes Roller problem . It seems my efforts are not going to be respected on this board. Carry on oiling

OBTW how was your Mower maintenance business - did customers want to pay for your time? or was it cheaper for them to go out and buy a flymo from BnQ

btw ps pm me if you want the inside track

and all their nipples where

and all model T nipples where visible and greased

Can anyone tell me if there

Can anyone tell me if there was ever a kind of plastic cap that went over the drum roller side bearing oil nipple. no photos ive seen show one?

Whilst seeing other mowers roller innards and noting the simple axle and loose clearance fit within the drum, it occured to me that it might be possible to dribble oil down the shaft fro the side panel by drill a 6mm hole at 12 oclock just say an inch above the bearing this dimension tbc by actual inspection. Then its a matter of tipping the mower at 45 on its side and using an ordinary oil can. Anyone favour this line of attack?

Or perhaps a simpler fix would be to tilt the mower as above and pump loads of oil in the bearing, excess dribbling down the shaft?

Can anyone tell me if there

Can anyone tell me if there was ever a kind of plastic cap that went over the drum roller side bearing oil nipple. no photos ive seen show one?

MBA1631

Parts list says 20” version

Parts list says 20” version only for some reason

Maybe a "model year" thing

Maybe a "model year" thing but my list shows the same number for both 18 and 20".

Edited, 07/08/18.

Here are the relevant pages from the Mk5 and 5M parts list. I very much doubt if the size of the access hole has varied year to year model to model and this list shows the same part for both Imperial and Metric machines which would suggest that even if the hole size has changed, it has been within the tolerance of the same grommet.

It may be easier to just measure the hole and buy the appropriate grommet from your local purveyor of such things!

https://www.dropbox.com/s/c7jye3q3d92mhw4/Ransomes%20Marquis%20grommet0…

Version that I have is for

Version that I have is for MK4A as that is mower I have but it does seem strange. Can’t remember where I got download from so will try and find out

Thanx for the exploded diag

Thanx for the exploded diag WP most helpful. I found a Wallace accessory on EB 10p will report if it works. every Mower will want one

In pursuit of oiling your

In pursuit of oiling your roller, I was struck with the notion than laying the mower on its side and pumping the bearing with my oil gun and its hydraulic nipples, then the excess oil may be squeezed out at the back sufficient to dribble down the shaft and lubricate the roller (and of course vice versa for the other side)

Does this seem like it will float?

I am getting to the stage where I must lower the mower from its stage in my garage and do some mowing and stop meddling. As one poster said, its not the time you spend on the bench - its 10x as much waiting for parts delivery

Trying to understand how you

Trying to understand how you can lubricate the rear roller bearings on a Marquis, they do not have grease or oil nipples and the bearings are sealed. Even if you could over lubricate them, the excess oil would not find its way into the roller half, all over it perhaps.

AFAIK and WP earlier advised

AFAIK and WP earlier advised roller bearings were of the open type and later went over to sealed for life bearings. Mine has nipples for oiling and I also got a 22mm cap grommet (10p) cos I dont like looking at dirty nipples - perfick

Every Marquis I have ever

Every Marquis I have ever seen (and I have a seen a very lot of them) has had sealed rear roller bearings. I am not saying that early variants didn't have rear roller bearing oil nipples, just that I have never seen any and I started looking at them in 1973.

If yours does have oil nipples, it is either a very early model that I have never seen, or somebody else has added them.

here a pic

here a pic

if you look closely you will see my grommet cap nipple cover between the 3 bolts holding the bearing carrier. the nipple was originally the straight type requiring a cup head oiler. Ive change all nipples except the internal roller drum nipple to the modern hydraulic type used in grease guns but i fill my gun with ep90

also the pic shows my much derided everlasting Super pugger Whisper Muffler I had the impression mine was '63. It was in the same family before for 50+ years till bereavement. I think maybe if I can get the mower on its side and access rear underneath then the oiling hole may be more accessible. I just find it a nasty operation, you probably only do once a year. Initially you really dont know what you are doing but I can see why WP rails against any form of greasing

I am rushing things a bit cos I need to get some lawn weeds cut down

Cheers

Plain bearings for the roller

Plain bearings for the roller shaft were fitted to early imperial Marquises , the ball bearings first appearing on 20” machines followed by 18” ones later. The oiler for the left hand bearing was on a tube that emerged through the engine platform adjacent to the traction clutch lever and push rod. The right hand one had a nipple in the centre of the shaft holding slot, behind the rubber bung.

Yes have seen the LHS one

Yes have seen the LHS one emerging from the platform with a shiny new brass nipple, but if the remove the chain cover there is another nipple on the clutch plate presumably for the clutch thrust rod?

Amazing a new Matador 71 is ca £5000. This is more than I paid for my year old Aygo. My Mattie is still stuck in my trailer - 160kgs for my chain hoist. Good nick all complete, grass box to sleep in, Jap engine all for £99. I couldnt help myself. Never mind the elephant in the room. NZ Annie and I are not speaking since she ran over me and laid me out flat, bad day and bruised ribs to follow

On every Marquis I have ever

On every Marquis I have ever seen, behind that cap there is a slot for one of the tools required to remove the roller driven sprocket (the one at the other end oof the shaft). I personally have never seen a grease nipple there, but I am not discounting it.

Why EP90 ? this is much too thick and will tend to attract dust & dirt and when you mix dust, dirt and thick oil, you get grinding paste. I also wouldn't use this if you ever get your hands on an Auto-Certes, it will attack the roller bushes.

Yes have seen the LHS one

Yes have seen the LHS one emerging from the platform with a shiny new brass nipple, but if the remove the chain cover there is another nipple on the clutch plate presumably for the clutch thrust rod?

No, it's mainly to lubricate the "top hat" bush and ring gear in the clutch plate both of which require SAE30 , but some oil will find its way ro the push rods.

Well Wristpin that is indeed

Well Wristpin that is indeed enlightening, many thanks

Another light bulb moment, I got a straight piece of 8mm small bor copper tube and cut off a pice ca 3" long. the cutter gave a clean edge. By poking about I was able to locate the nipple head and slide the tube over it. I then plugged my nasty chines oil can into the tube and pumped away, and managed to build up some pressure and maybe was injecting some oil. Trouble is , how do I know if its enough, are there any signs to look for? Or just pump away and hope for the best?

How does the ratchet side of things get lubricated?

For interest, what is the diameter of the nipple head? Maybe 6mm tube would be a better choice

I have to say that intuitively I am wondering if using oil instead of grease is an urban myth. All this about grease drying out and hardening and blocking oilways? If exposed to high temp you get problems for sure, but thats just and old biker spouting

I can see myself not being happy about any of this till I have the rollers apart

I did once ago have to help a pal out with his combine harvester. I was appalled at some of the engineering bodges deliberately designed to fail after a few years (well out of guarantee. For example making grease points hard to reach or obscured and needing dismantling of pulleys etc. One of those machines is a bit like an elephant. I like looking at them but I wouldnt want to own one.