Suffolk Super Punch Magneto Info

Hi,

I have a 17inch 1956 punch that broke a bearing link that i replaced. As it was stripped down and the 75cc engine was spluttering I decided to do a bit of maintenance, cleaned carb and repainted but on testing I found no spark.

Cleaned points and checked gap, fitted new plug and suppressor but still no spark.

Removed flywheel and cleaned around points as there was slight contamination removed plug and suppressor spun flywheel with electric drill and still no spark between HT lead and engine.

Spoke earlier to jon Cruse who thought it was most likely points/gap but it does not seem so.

I also re-tightend screws on backplate around HT coil and checked earths with multimeter.

The Magneto is the one shaped like a crab and was replaced about 7 years ago, it has separate capacitor/points and coil. The multimeter does show some voltage "flicker" but of course cannot see any HT. I can however see the secondary resistance is about 3.5k ohms which from memory seems OK!?

Other than the capacitor can anyone give some guidance as to what to try next or suggetions as to what might the problem?

Thanks

PS Jon thought it was unlikely to be the capacitor!

Peter H

Forums

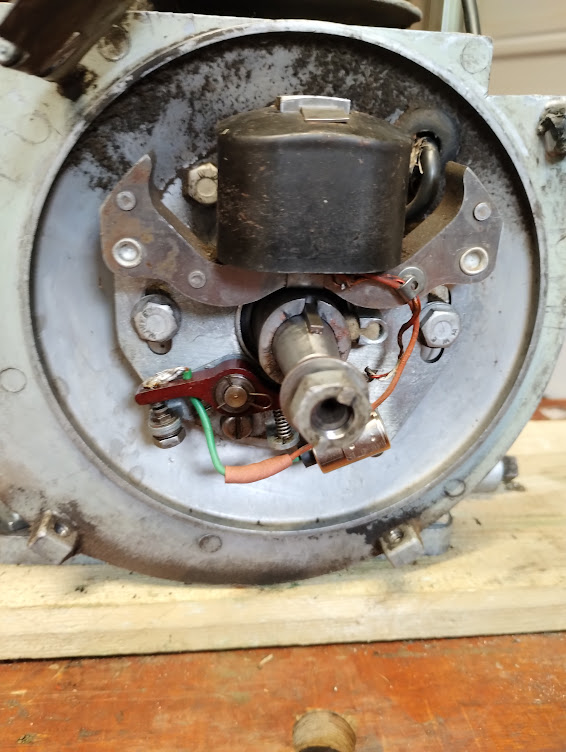

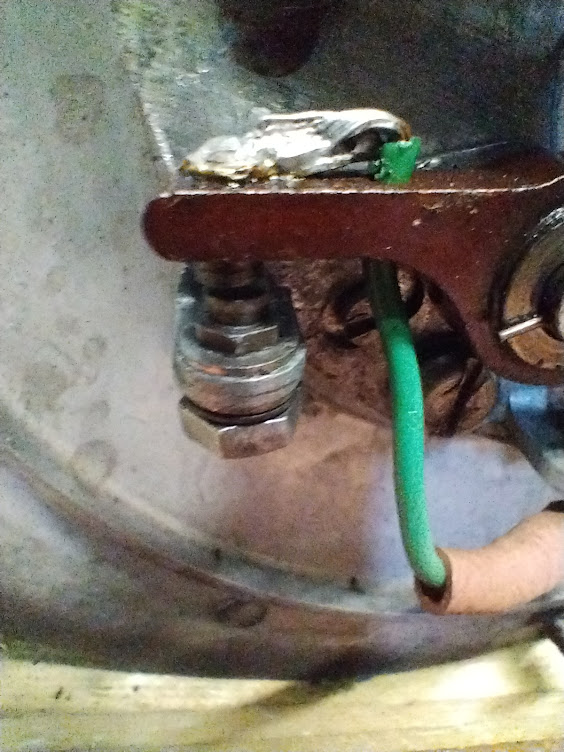

Hi, Attached are some images…

Hi,

Attached are some images, I do sometimes get it to fire but still has weak or no spark.

After reading through some old posts, I will remove magneto, clean backplate and re-solder contact joint which does not look good! I will also dismantle and realy check points!

My multimeter can check capacitance, what should it be, 100nF!?

I agree with Jon that its most likely points but have had capacitor issues in the past causing weak/intermittant spark.

Anyting else I should consider doing!?

Thanks

SUCCESS! After reading…

SUCCESS!

After reading another thread of about 2yrs ago what said it was difficult to clean points without removing magneto, I did just that!

They were slightly pitted but even after cleaning them with emery cloth they were still quite black. I re-cleaned them and re-soldered joints while it was dismantled. I set timing to nearest I could judge. Is there any easy way to set them 20 degrees BTDC!?

It seems Jon C was right 80%-90% of ignition problems are points cleanliness. I think my problem may have been over maintenance! In the past I have oiled moving parts and it looks like the points may have been contaminated as the oil seal to the crankcase is OK.

The points are now bright and it slow runs smoother than for the last few years and it may be more powerful when I set the timing more accurately!!

Thanks

Timing. The SIF cast iron…

Timing. The SIF cast iron engines are fairly tolerant but 23 degrees btdc is the book figure..One of your images shows the stator holding bolts in about mid slot, and that’s usually “ good enough but the first step is to set the points gap to the figure that’s usually stamped into the flywheel - the book says 18-20thou. After that you will need to download and print a timing disc to mount on the crank to check that the points are opening at the 23 degree mark , which you can check with your multimeter and adjust by moving the stator.

If it’s running and performing satisfactorily as it is, I’d be inclined to leave it alone !

A bit surprised at JC ‘s…

A bit surprised at JC ‘s comment as I find quite a few failures - either total or weak . Can your multimeter measure capacitance? As the mag has been changed is it still of the original pattern with what I call “see saw “ points. An image will be useful. I’ve found a few cases where they are not closing firmly - you can check with the multimeter.