The Cross Cut Machine

Newly-woven woollen cloth often has an uneven surface with tufts and bobbles caused by the natural fluctuations in the thickness of the threads and the weaving process. To create an even and smooth surface the new fabric was teased to raise the nap (the fluffy surface of the cloth) and then sheared by hand but this was a time-consuming and laborious process that was typically done by a skilled shearsman using clippers or shears.

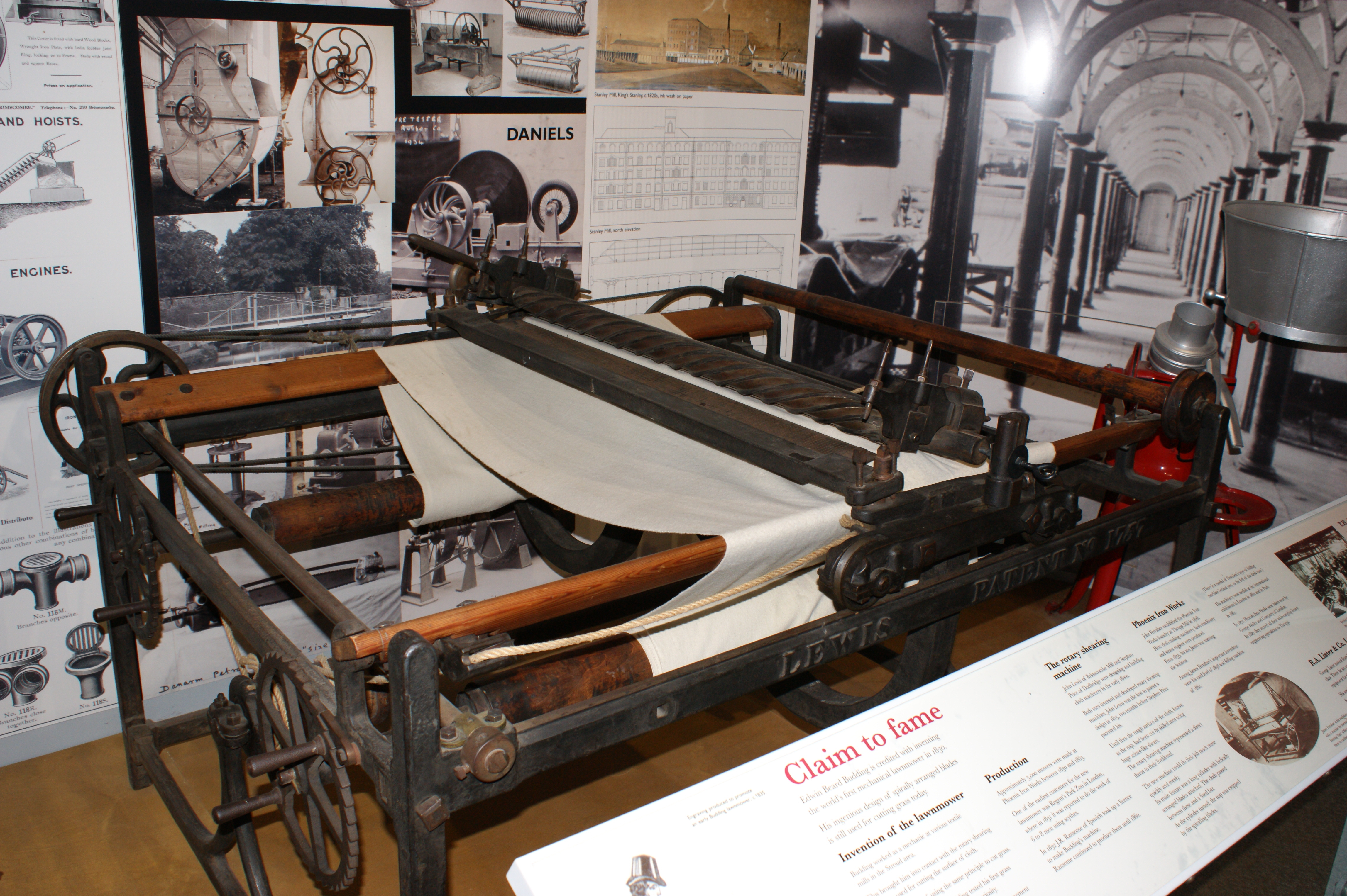

Various people tried to devise a way to mechanise the shearing process but none was very successful. In 1815, however, an engineer called John Lewis who was working at Brimscombe Mill came up with a new type of machine. Known as the cross cutter, this was designed to finish the cloth by trimming and smoothing its surface. Lewis registered the design under Patent No. 3945 in July 1815 and it was introduced in 1818. By 1829 it is said he had sold several thousand machines.

Its design and operation was ingenious...

The machine was roughly the size of a double bed and it was built around a cast iron frame which in addition to being strong would have provided a rigid and stable base for the work in hand. Attached to this are various wooden, leather, and metal components to secure, tension, and trim the cloth.

The section of cloth to be trimmed is held in tension cross-wise using hooks along its edges (known as the selvedge or list). The cloth is held in tension length-wise by the rollers mounted under the frame which carry the length of cloth. A frame comprising wood and leather provided a secure and firm bed underneath the cloth being trimmed.

The part of the machine that concerns the history of the lawnmower is its cutting mechanism. A spiral cutter extends across the width of the machine. A fixed blade - known as the ledger blade - is mounted beneath it across the whole length such that the two are barely touching. The drive mechanism ensures the spiral rotates quickly to provide what it effectively a continuous shearing or scissoring action in conjunction with the fixed blade. At the same time the entire cutter mechanism is drawn mechanically across the surface of the nap (cloth), with the speed of rotation and travel held in synchronisation. In this way the cutter trims the cloth evenly and consistently as it moves across the surface. Once the section (known as a "board") has been trimmed, the cloth is unhooked and the rollers under frame turned so that a new section is now on the bed. The cloth is then re-hooked and tensioned in both directions before the mechanism is passed over it.

Various levers, pulleys, and wheels allowed fine adjustments to the tension of the cloth and the speed at which the machine could operate. The entire machine was powered by a belt connected to an overhead rotating shaft driven by the mill's waterwheel or, later, steam engine.

The invention of the cross cutter meant that any length of cloth could be trimmed quickly to produce a consistently smooth surface. Contemporary reports suggest one machine could trim a length of 21 yards (approximately 20 metres) in about two hours. Two machines could be worked by two boys supervised by a man. Much more cloth could be processed each day, and with far fewer people who had lesser skills, than with the previous manual methods. The machine was so successful that is quickly replaced the shearsmen in many mills in the area and further afield. Modern machines work on broadly the same principles.

Today, we can recognise that the cross cutter has many similarities with the original lawnmower.

Read more about the Cross Cutter at the Stroud Textile Trust.