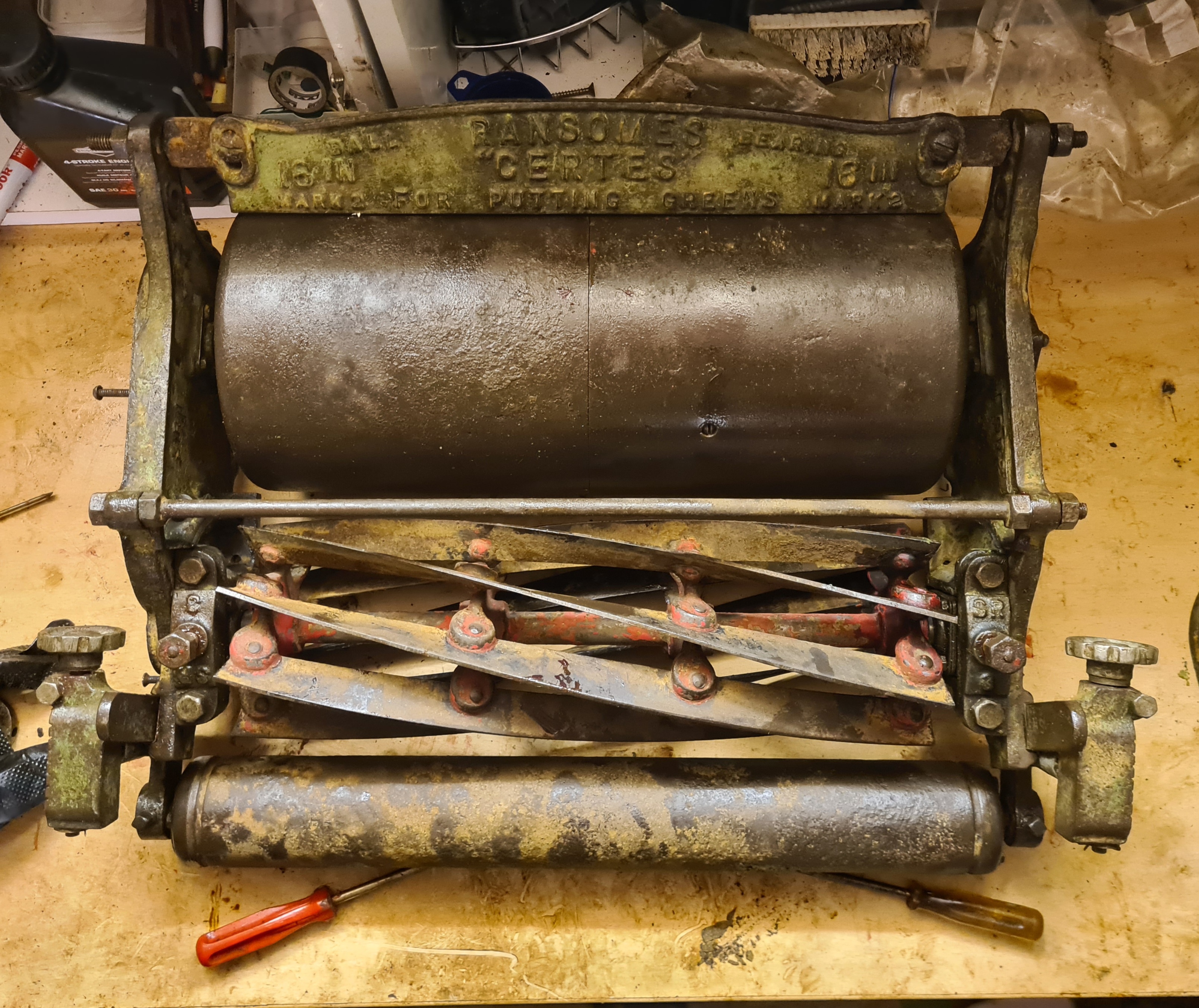

Ransomes Certes Mark 2, 16in push mower

I have recently acquired a Ransomes Certes Mark 2, 16in push mower from a neighbour so that I can restore it. It was originally used for their tennis court, but probably not been used for 50 years. I think it is in remarkable condition for it's age. It also includes the carrying wheels.

I have watched a YouTube video from Lawnmower Jones to help me partially strip it down, but I do not want to go any further to ensure I do not do something which I am later told I should not have done.

I am a complete novice in this area and have joined your club to see if I can get any advice and recommendations to ensure I do the best job I can.

Any comments welcome.

Forums

That's great advice from…

That's great advice from Keith & taking your time if something is stuck don't force it, many of us have learnt by snapping off nuts/bolts. If stuck, clean around thoroughly & soak, I have often used a diesel bath & left parts in soaking for several days. And of course a bit of heat from a blow torch, away from the diesel!!

The Mk1 Certes was introduced 1925 & your Mk2 around 1930, the blades don't look too rusty & you may be able to find a date on the underside of each blade in this format 29/30 the numbers being around 4mm, often the / stands out more, this does not necessarily date the mower as cylinder in some cases may have been replaced but would be interesting to know.

A great mower to start off with & the bonus of carrier wheels & grass box which is often missing on the early ones. Keep us posted.

Thanks both, appreciate the…

Thanks both, appreciate the comments. I have taken lots of photos and tried to separate the different items into groups, but I think I will now take the time to label everything. Many thanks

I have come across two…

I have come across two issues if anyone can help. The first is quite simple the bottom blade is connected by 4 screws. I have put WD40 on and left for a while, but do not seem like they want to budge. Taking your advice of not forcing I have put some more WD40 on and left it. See photo, any suggestions.

The second is trying to remove the cutting cylinder. I have removed both clamps and springs and both sides can move up and down, I can completely lift up the side opposite the gears, but the problem is the side near the gears has a rod coming through which prevents me lifting it any further. The video I watched showed this being removed and all he did was wiggle it a bit and it came out. It does not want to come out for me. See Photos and any suggestions. Thanks in advance.

You need a good impact…

You need a good impact driver to mover those screws. Soak in oil WD40 isnt that great .

Thanks Chirpy, I used some…

Thanks Chirpy, I used some better oil and got my friend to help with the impact screwdriver and now have it all in pieces. It is in much better condition than I thought with all the bearings, and gears in good working order and the bottom blade is in great nick. The tips on the forum and the web site were very useful, especially the don't force it, take your time. I will now learn about stage 2.

Well done, keep us informed…

Well done, keep us informed on progress a Certes is a fine mower that deserves saving.

Thanks for your help so far,…

Thanks for your help so far, I am moving forward slowly but would appreciate some advice and guidance.

- The Housing Cylinder L.H. is stuck on, it moves but then seems to hit something with a clunk. I do not want to force anything, but I can not see what could be holding it on. Should I just pull harder? See Photo 1.

- After cleaning the side frames there is still a lot of lime green paint on them and on other areas of the mower. I feel with further cleaning I could make this even better. The question is should I remove the paint completely, paint over or leave it in it's natural state. See Photo 2.

- A similar thing with the spiral cutter but I think that is more clear cut to repaint. Should I also get it sharpened before painting and if so who would do this? I live relatively near Southport, is this something the Lawn Mower Museum could help with? See Photo 3.

- The front roll is very rusty and pitted, if I keep going at the rust will it improve or do I just have ti accept that is how it is? If I should get rid of more rust should I put in vinegar and use a wire brush? See photo 4

- Both the wooden Handle Grips have a split in them. Is this something I can replace or should I just fill with plastic wood? If I should repair, should I try and do this in situ or try and remove. My concern is trying to remove will break them. See Photo 5

- The Handle Assembly again has a certain amount of green paint still on. Like point 2, should I paint or leave as it is. If I need to clean and de-rust are there any suggestions on the best way of doing this? I could put in a big bath of vinegar to remove the rust but that will aslo remove the paint. See Phot 6.

Not sure about point 1 ,but…

Not sure about point 1 ,but regards the other cylider and front roll you might be better off getting a new cylinder and bottom blade from Garfitts, wont be cheap but money well spent in my opinion. Regarding the front roll can you put it in a lathe and take a millimetre or so off? Or if you kave a bench grinder use that.

Thanks Chirpy, It does not…

Thanks Chirpy, It does not look like my photos have come across. The cylinder is in very good condition, so I do not really want to replace it. I would like to keep as much original parts as possible. The more I look at it the more I feel I also want to keep the original paint, apart from on the cylinder which I will paint red. I am not sure if that would mean it will get rusty again very quickly.

Hi Clive, I do not seem to…

Hi Clive, I do not seem to be able to see any dates on the Cylinder blades, but I have found a few letters that looks something like RR&d. Do you know what the letters are and have they any significance?

I thought the bearings were…

I thought the bearings were OK, but a mechanic friend of mine said it would make sense to replace the bearings. I can see they are SKF and Made in Sweden but can not make out any of the other letters and or numbers. Does anyone know what they are and represent? Would all the bearings be the same on the mower or could the roller be different to the cylinder? Also how easy would it be to get replacements and do you agree they should be replaced while it is all apart? Many thanks for all your help. I am going skiing for a week, so I will not be pestering you for a while.

The letters stamped on the…

The letters stamped on the blades are RS&J which is of course the manufacturer's abbreviated name.

The bearings should be easy to replace. These are "stock" items in that they are generic units made to standards which are still in use today. SKF is one of the largest manufacturers but there are many others.

Although the code numbers may not be legible it is generally possible to identify any bearing using three dimensions: the internal diameter of the hole in the middle; the external diameter; the thickness of of the bearing. Bear in mind that these measurements will "Imperial".

There are several bearing suppliers that can easily be found online and most allow you to enter the dimensions, after which they will suggest which items they stock will fit. Many also show photos so that you can compare them with your own unit. Expect to pay a few pounds for each one, well worth the investment if you are planning on using the mower or the ones you have are damaged.

Two companies I have bought from in the past are:

https://www.wychbearings.co.uk/

https://simplybearings.co.uk/shop/

If that seems too tricky, there is probably a supplier near to you on a local industrial estate. Most large towns still have one. Simply take the bearings you want to replace and they will help you.

Incidentally, I did some marketing work for SKF many years ago and one of their selling points was that they could supply a replacement for any bearing they had ever made during their entire history. I am sure they could say the same thing today.

I have been spending the…

I have been spending the last couple of weeks cleaning the parts mainly with Jizer. I have decided to keep as much of the original paint and parts as possible. I do need new felt washers I think the part number is LO10 Felt Washer for cylinder bearings. I attach a photo, but I get the size to be 33mm diameter and 21mm inside and about 7mm I think. Can anyone suggest where I can get two.

After cleaning up the grass…

After cleaning up the grass catcher I found it still has the transfer on it.

Re the felt washers, there…

Re the felt washers, there is an abundance on-line, suggest you look through for a similar size, you can also buy sheets of felt to make your own, or look to have some made.

Thanks Clive, I have looked…

Thanks Clive, I have looked online and although I can see felt washers, I am not able to specify the dimensions. Are you able to point me towards a suitable site. If not where could I buy the felt, and if I made it myself could I just use scissors or do I need specialist equipment?

Probably difficult to cut…

Probably difficult to cut yourself from a sheet of felt, assume they are pressed, just need to keep searching for the appropriate size.

Noting your comment re letters on blade which Keith has answered, were these on the top side or bottom, the date is usually on the bottom. Might be difficult as the letters are only just legible & the date will be smaller & not necessarily near to the letters.

I'd suggest contacting a…

I'd suggest contacting a company such as RH Nuttall in Birmingham (there are many other suppliers).

https://www.rhnuttall.co.uk/washers/felt-washers/

Tell them what you need the washers for and the internal and external diameters of the ones you need (measured from your old ones). It's likely that these are going to be standard sizes so price may not be too bad. But no harm or obligation to buy in asking them.

If you did want to make your own, probably best to use some kind of circular punch...

https://www.ebay.co.uk/itm/Round-Hollow-Punch-Set-Hand-Tools-Hole-Punch…

...but by the time you have bought the right sizes and the material you would have spent quite a bit more than buying the washers ready-made.

Thanks Olcadmin, I have…

Thanks Olcadmin, I have ordered from R H Nuttall they were very helpful.

While checking the land roll…

While checking the land roll I noticed one side was turning, but the other was attached to the spindle and no turning. The question is how do I remove the red fastener and the land roll. I have removed the bolt that holds the red fastener in place and put some loosening oil between that and the spindle. On the land roll, you can see there is a hole (which was filled by a screw that I removed) and below this is a tube which seems to lead to the spindle. I presume this is to put oil in for the bearings. I have sprayed loosening oil and WD40 in the hole to try and clean and loosen it. Any suggestions or comments would be greatly appreciated.

The roller is fixed, I could…

The roller is fixed, I could not remove the fasteners but while trying to bash them off it freed the second roller so never found out how to remove them.

The greenkeeper at my golf club has sharpened the bottom blade, but needs the mower rebuilt to try and do the cylinder. So I rebuilt today and looking really good.

I have not got the felt seals back yet so I might have to take the cylinder off again, when they arrive, but when rebuilding the original seals seem to be OK.

I did not realise the front roller would need to turn, (obvious really) but fortunately that seems to have loosened it self during the cleaning process. Unfortunately it is the most rusty and I will need to think what to do with it.

So need to put the cogs back after I sharpen the cylinder, repair the wooden handles, weld the grass bin and then put the last few bits on.

I am pleased to say that the…

It's finished!

I am pleased to say that the mower is now complete. I have used all the existing parts.

First time rebuilding I had a spare nut and it took me a while to figure out it goes on the end of the cutter away from the gears. My problem is I do not have a manual for Mark 2, so I had to look at newer models and they seemed to vary.

I got the greenskeeper at my golf course to sharpen the bottom blade and the main cylinder cutter.

A friend welded some sheets of metal on to the holes in the grass catcher, it is not very pretty, and all I have done is sprayed undercoat on it.

I have not done any painting as I wanted to keep as much of the original as possible. I will wait for any reactions, but if needed I am confident I could now quite easily take apart to paint before reassembling.

The mower works very well although at the moment it is on the highest setting, but as the quality of the grass area I am using improves I will lower the cut.

Thank you all for your help, it is much appreciated.

Well done, enjoy using it!!!…

Well done, enjoy using it!!! Regarding the paint, the look of the mower would be much improved with a coat of paint especially the handles, a coat of hammerite or enamel would take you 20 minutes. Even less time if you used a rattle can!!!

Thanks Chirpy, maybe that's…

Thanks Chirpy, maybe that's my next project,

My Ransomes Ajax Mk3 has…

My Ransomes Ajax Mk3 has similar or the same handles. Mine were also badly split so just made two new ones on the lathe. I worked at RS&J lawn mower works from 1965 to 1970. Never saw one like yours, much earlier !! Re. the collars that hold the rollers inplace, warming them up might help remove them. It would be favourable to check out the pawls in the rollers and to lubricate the various parts before final assembly.

Mike.

Thanks Mike, in the end I…

Thanks Mike, in the end I just put in some plastic wood and it sealed the cracks.

Nice mower to start a…

Nice mower to start a collection and a bonus to have the box and some transporter wheels.

For newcomers, I think it's always good advice to go slowly, take lots of notes and photos, and never force anything that appears to be stuck.

Most components will come apart easily enough. If anything is stuck, be patient and use lots of penetrating oil or a similar product designed to unseize them. It's rarely a good idea to force anything.

Pay particular attention to washers and nuts and their position or location. Most of us know how it feels to finish a restoration and find we still have a few left over with no idea where they should be.

Bear in mind that some components and assemblies will be "handed", in other words designed to work in a particular direction. For example, the components inside the roller and drive are made such that they will drive the blade when the mower is pushed forward but will stop when the mower stops or is pulled backwards. This may mean that when you think you are undoing a nut or bolt you are in fact tightening it.

Takes lots of photographs at every stage. Your smartphone or digital camera is your friend and these photos will be invaluable when you start to reassemble the mower.

Search the forum for other members' stories and experiences. There is lots of information here and even if your particular mower isn't featured, the problems faced by other members are likely to be similar. Most mowers have a fairly basic design, after all.

Ask more questions on the forum. I am sure other members will be happy to offer advice and encouragement, and many will have preserved or restored a similar if not identical mower at some point.

Finally, there is some general advice on mower restoration on our site at the following link. Hopefully it will provide some useful hints.

https://oldlawnmowerclub.co.uk/mower-restoration

Good luck and keep us posted on your progress.